Between the end of the Winter War in late 1940, and the re-entry of Finland into WW2 as one of the Allies fighting against Germany, Finland introduced the Czech/Finnish-designed and built Patria M/42 Valkosusi into service. One of the main contenders for the “best tank of WW2”, the Valkosusi was a lethal weapon when fought to its strengths. This is the story of Finland’s Main Battle Tank of the last years of WW2.

By the end of the Winter War, it was obvious that the Finnish M/39 Panssarinhävittäjä, whilst a capable armoured fighting vehicle, would all too soon be outclassed by the heavy Russian tanks that had begun to be seen in small numbers in September and October 1940. In addition, the M/39 Panssarinhävittäjä was more of a tank destroyer, suited to the defense but not to the tactical offensive that was at the heart of Finnish war-fighting doctrine. It was an effective armoured fighting vehicle on the defensive (and indeed, would remain in production until 1945 and in service well into the 1950’s with the Finnish Army) but it was not the tank that the Finnish Panssaaridivisoona’s doctrine called for.

Likewise, the Patria M/38 Sotavaunut, based on the same chassis and hull but with a Swedish-built turret, had an outclassed 37mm gun that could do nothing against the heavy frontal armour of the newer Soviet tanks such as the KV-1 – although still effective from the sides or rear. The M/38’s fairly lightweight armour, while adequate in the Winter War, could be shredded by the new Soviet tank guns that had been encountered in the last weeks of fighting (and indeed, by the Finnish Army’s own 75mm anti-tank guns) which did not bode well for the future. Likewise, the Bofors 37mm gun, the main armament of the Sotavaunut M/38, could do nothing to the prototype Soviet T-34 tank’s thick, sloped armor plate (although side or rear shots were still effective – but much harder to get in position for). Conversely, the high velocity Bofors-Tampella 76mm gun with which the Patria M/39 Panssarinhävittäjä was equipped had proved itself quite capable of taking out the new Soviet tanks.

One result of the immediate post-war reviews that were completed within weeks of the war ending was a recommendation to urgently develop a more capable, better protected and better armed tank capabe of taking on the new model Soviet tanks on an equal footing. This was without any doubt inspired by the latest model Soviet T-34 and KV-1 tanks encountered in the last weeks of fighting of the Winter War, many examples of which had been captured and which were available for study. A special commission, consisting of Patria engineers and the Škoda and CKD engineers and designers who had remained in Finland (or who had previously left to find refuge in Finland for various reasons) was formed to study the adversary and design a solution. However, it was understood from the start that to develop a completely new tank would take too long and be too expensive.

The design team was formed in December 1940 and given the goal of having a draft design ready by the end of April 1941. Study of the newest captured Soviet tanks together with almost a year of continuous combat against the Red Army had resulted in the identification of numerous areas where improvements were needed and/or could be achieved. Most critical amongst these were:

- Increased thickness of armour, particularly frontal armour but also side armour;

- Sloped armour, which would improve shot deflection and increase the effective resistance to penetration;

- Welded armour rather than riveted;

- Wider tracks to decrease ground pressure and improve mobility over soft ground and snow – something that the Finns, with their experience in building heavy tracked vehicles for use by the logging industry in winter, would exel in);

- A low centre of gravity and a low profile;

- A more powerful engine offering greater speed: one of the most frequent recommendations made by surviving tank commanders was that speed was essential: “Tanks must be fast. That, I would say, is the most important lesson of the war in regard to tank design….”;

- Preferably a diesel engine to increase survivability if hit;

- Larger fuel tanks giving an extended range, meaning less frequently required refueling;

- Mechanical reliability and serviceability: Engines and parts must be reliable and easy to service;

- Extended track life: average track life should be at least 2,000 miles (in the Winter War, the average track life of both the Sotavaunut M/38 and the M/39 Panssarinhävittäjä was approximately 500 miles;

- “Fire-power, armor protection, speed, maneuverability and cross-country performance are the essentials, and the best type of tank is that which combines these conflicting requirements with the most success. As low a silhouette as possible should come next….”;

- A turret for the Bofors/Tampella 76mm gun, the gun turret should come with a turret basket (a rotating floor that moves as the turret turns);

- A power-operated turret to increase the speed of traverse and subsequent target acquisition;

- A 3-man turret with provision for commander, gunner and loader: one of the major lessons learnt from the French-supplied tanks used by the Finnish Army in the Winter War was that it was impossible for the commander to effectively act as the gunner at one and the same time (Suggested crew of 5 – Driver and radio-operator/hull machine gunner in the forward compartment, commander, gunner & loader in the turret);

- Every tank must be equipped with radio;

- External Intercom on the back of each tank for communication with accompanying infantry;

Other key considerations were:

- Ease of manufacture (as few manhours as possible)’

- Reuse of as much of the existing armoured fighting vehicle production line as possible to minimize retooling requirements;

- Dimensions restricted the height, width, and weight so that it could be transported via typical bridges, roads, railroads (and potentially landing craft) without any special accommodation. This was intended to aid the strategic, logistical, and tactical flexibility and mobility of the armoured forces;

The design team was made up of a small number of Patria, Tampella, Škoda and CKD engineers and designers (the Škoda and CKD engineers were largely refugees who had been working in Finland with Patria when Czechoslovakia was taken over by the Germans and who had elected to remain in Finland) together with selected Panssari officers and by April 1941 they not only had a completed design, they had built half a dozen wooden mockups plus one working prototype (built with soft steel). The tank, subsequently designated the M/42 Valkoinensusi, was based on a chassis that was an enlargement of the M/38 Sotavaunut / M/39 Panssarinhävittäjä with a conventional track design with a brand new turret modeled somewhat on those of the Soviet T-34. The tank would be powered by a 450-horsepower Finnish-manufactured Hispano-Suiza inline aircraft engine while the main gun was to be the Bofors-Tampella 76mm used in the M/39 Panssarinhävittäjä that had proven so effective in the Winter War. Armour was significantly thicker than with the earlier tanks and at 25 tons weight overall (for the initial design), with its wide tracks, good off-road mobility and powerful engine, the proposed M/42 Valkosusi promised to be a very capable armoured fighting platform.

One of the early issues for Patria when they first began building tanks had been tank turret construction, in particular the turret rings, an issue that was the partial origin of Patria’s Panssarinhävittäjä design – initiated when a major bottleneck was encountered with turret ring manufacturing. However, with the assistance of Škoda engineers, this issue had been resolved in late 1939 and by late 1940, Patria was able to manufacture their own turrets, no longer needing to rely on Bofors in Sweden to build these. With the expertise so painfully and lengthily acquired on turret design and build for the Sotavaunut M/38, Patria was able to come up with a vastly improved turret for the M/42 Valkosusi (and for this, the contribution of the Škoda and CKD engineers and designers should be gratefully acknowledged – Patria’s success was very much due to the whole-hearted contribution of the Škoda / CKD team’s industrial engineering expertise and knowledge).

A wooden mockup of the Patria M/42 Valkosusi turret was constructed on an existing M/38 chassis in tandem with the design and presented to the Review Committee on 29 April 1941

Multiple objectives were set for the new turret – it had to be as low as possible, in line with one of the tank’s major design goals being a low profile overall. It had to accomodate three crew members (commander, gunner and loader), it had to have a powered traverse independent of the main engine and be capable of turning 180 degrees in 15 seconds. It needed to accommodate the Tampella-Bofors 76mm gun and ready ammunition storage needed to hold at least 60 rounds of main gun ammunition, with provision for further ammunition storage within the tank.The hull and turret should also be cast or welded, with no riveting and without a single vertical surface; the goal being to have no shot traps. A wooden mockup of the new turret was built early in the design process to assist with design decisions on the placement of internal components. One of the outcomes was that a turret basket was added to the rear of the turret (an additional basket was later added to the rear of the tank in order to allow 10 jerrycans of petrol to be carried, permitting range to be extended somewhat).

With the 76mm main gun in mind, the size of the new tank design was increased overall to allow a larger (1820mm/182cm turret ring) 3-man turret, with provision for a loader as well as the gunner and commander. The larger turret was also redesigned to include a large back extension for added ammunition storage (to a total of 137 main gun rounds) and was designed with an integral turret basket (a rotating floor that moves as the turret turns). The large back extension to the turret also served as a counterweight to the main gun. The turret could be rotated either mechanically, or via an electric drive that ran independently of the main engine. While the turret crew main entry point was situated on the right side of the turret roof, experience in the Winter War had also demonstrated that one hatch in the turret was often insufficient for evacuation of the tank when it was hit so a second hatch was added besides the commander’s. An external pedastal-mounted Lahti 20mm cannon with a box feed was added to the turret for the tank commander to use while the main gun was paired with a coaxial 7.92mm heavy machine gun in the same mount (2,000 rounds of 7.92mm ammunition was also stored within the turret). Perhaps the greatest thing about this turret was its ability to depress the gun, the depression was 15 degrees giving it an insane hull-down capability which the Finnish tank crews would use to their advantage when fighting against the Germans through 1944 and 1945 (and now and then against the Red Army as well).

The ability of the M/42 Valkosusi to depress the main gun up to 15 degrees gave it an insane hull-down capability – and an ability to “snipe” from behind cover which Finnish tank crews grew to appreciate deeply in the fighting of 1944 and 1945

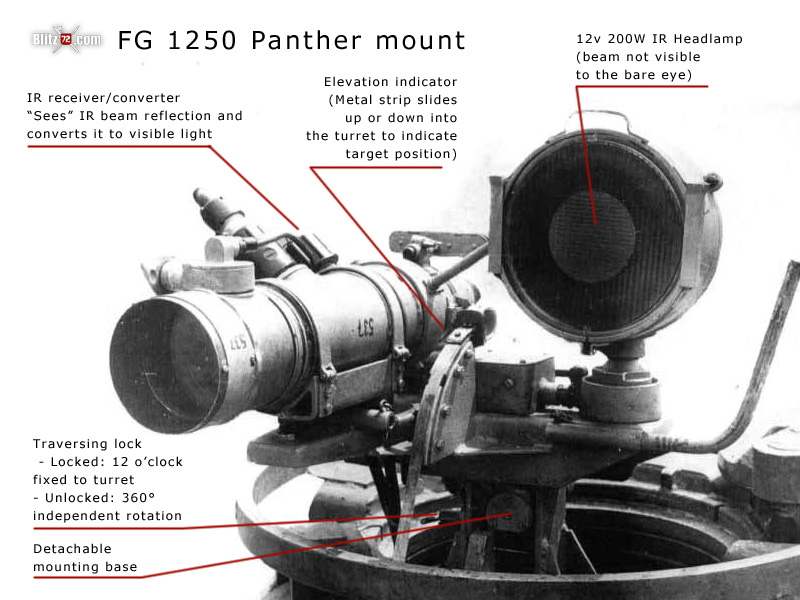

For reconnaissance and exterior viewing in battle, a rotary periscope was installed on the turret roof. Nokia Infra-red active night viewing equipment was proposed as standard. The active night vision for the gunner consisting of a Nokia infrared search light, and passive night vision optics for the driver, gunner and commander. The commander also had a passive night vision sight on the rotary periscope, featuring an image intensifier not unlike that used in night vision goggles. The combination of active searchlight and low level television gave the M/42 Valkosusi a night-fighting capability not matched in other tanks until the 1970’s, although its advantage was in the late ’70s was rapidly reduced with the increasing use of solid-state electronics and the quantum leap in microelectronics production beginning in the 1980s’.

Finnish Army Patria M/42 Valkosusi turret hatch with Infra-red night fighting device mounted. By mid-1944, almost all Finnish Army Tanks were also fitted with these Nokia IR systems, giving the entire Finnish armoured force an effective night-fighting capability, something the Finns used to full advantage.

Internal communication within the crew was performed thru an on-board Nokia communications system (or via light signals should the intercom go down). An external communications hookup was provided on the rear of the tank so as to allow easy communication with accompanying infantry. Provision was also made for three Nokia radios enabling Platoon, Company and Battalion communications to be maintained simultaneously by all tanks within a Panssaripataljoona. This radio network had only been in its infancy in the Winter War but its effectiveness had been well-proven, having been used to co-ordinate communications between head-quarters, air, armoured, artillery and infantry units throughout the fighting.

The radio network linking armoured command, observation and communications vehicles and radio equipped combat vehicles that had proven so effective in the Winter War was to be vastly improved on between 1941 and 1943. In the fighting of 1940, their radio network had given the Finnish commanders both a clear picture of the battlefield and the means to direct their troops as quickly and precisely as possible. This network allowed the panssari to penetrate deep behind enemy lines whilst maintaining constant contact with headquarters. It also allowed them access to the latest reconnaissance reports and to be deployed at a moments notice. Well trained panssari commanders were frequently given the freedom to exploit this advantage to the fullest extent and certainly, the rapid and fluid Finnish advances in 1940 would not have been possible without radio. The combination of wide radio distribution and thorugh radio training had proved invaluable to Finnish armoured units in 1940 and with the new tanks and armoured fighting vehicles with which the Panssaridvisoona were being re-equipped from 1942 on, it was intended to expand on these capabilities.

The hull was split into two parts by an 8mm thick armor plate with the crew compartment in the front and the turret set above it. The propulsion (engine) and fuel tanks were at the rear. The front compartment had two seats (driver to the left, radioman/hull machine-gunner to the right) with access for both of them to the turret. Both hull crewmembers had their own viewports in the hull, covered by armored shutters. Viewports were also present in the side armor for both crewmembers (without the shutters). These side sections with viewports could be opened and used as entry points for the driver and the radioman. The radioman/hull machine-gunner operated a 7.92mm mounted in the front hull on an independent mount with 2,000 rounds of ammunition. The engine compartment space was designed to be watertight so that the M/42 could be submerged and cross waterways (a snorkel was designed in for this purpose, giving the M/42 the ability to ford water to a depth of 1.7m / 5 ft 7 inches).

Overall dimensions of the M42 Valkosusi were:

- Length (hull only): 22 ft 6 in (6.87m)

- Width (hull): 10ft 9 in (3.27m)

- Height: 2.49m

- Combat Weight: 30 tons

- Performance: maximum road speed of 35mph

- Operational Range: 250 miles

- Tracks: 460mm wide, 0.68 kg/cm^3 ground pressure

- Vehicle to be designed to cross a 265cm wide ditch, wade in 120cm of water, and climb a 40 degree incline

- Main Gun: 76mm Tampella-Bofors with Tampella-Skoda 20 round autoloader

- Secondary armament: 1x20mm Lahti cannon, 2×7.92mm machineguns

Armour was strategically thickened to offer additional protection, while welding rather than riveting was used. The M/38 Sotavaunut chassis and hull had been widened and lengthened, the M/42’s tracks were also widened to keep ground pressure low (weight had increased to 25 tons overall), provide better traction and a larger 450hp engine was specified. Smoke and defensive grenade launchers were also added, along with a protective thin (in fact mesh) layer of spaced armor. The front and side armour was well-sloped and built only with a homogeneous steel glacis plate. The armor for the side hull and superstructure (the side sponsons) was much thinner at 60 mm). The thinner side armor was necessary to keep the overall weight within reasonable bounds, but it made the M/42 vulnerable to attacks from the side by all German and Soviet tank and anti-tank guns. Finnish tactical doctrine for the use of the M/42 Valkosusi thus emphasized the importance of flank protection. Finnish tank crews were well aware of the weak side armor and made unauthorized augmentations by hanging track links or spare roadwheels (or even fastening logs of wood) onto the hull sides;

- Hull front, lower: 100 mm @ 55°; upper: 160 mm @ 55° [lower: 80 mm @ 55°; upper: 120 mm @ 55°]

- Hull side, lower: 60 mm @ 90°; upper: 60 mm @ 65°

- Hull rear: 60 mm @ 60°, 60mm @60° twin side hinged doors (engine servicing/rearming/escape/)

- Hull top: 34 mm @ 0°, 4 mm @ 0° (ammo store)

- Hull bottom: 40 mm @ 0°

- Turret front: 180 mm @ 80°, [120 mm @ 65°]

- Turret side: 80 mm @ 69°, [80 mm @ 65°]

- Turret rear: 80 mm @ 70°, [80 mm @ 65°]

- Turret top: 44 mm @ 0–10°

Skirt armour 5mm thick would later be fitted to the hull sides. The curved turret and the mantlet shape gave added likelihood of any shells hitting the turret being deflected. With the considerable extra weight that had been added, the chassis design was strengthened. The front was reinforced, shock absorbers replaced and steering gear substantially modified. A new track design substantially increased off-road traction. The Hispano-Suiza engine was fitted with direct injection rather than carburetors and an engine silencer was added. Together with a number of other cold-weather modifications, fuel consumption was lowered and the engine could cold start from -25º C. And engine warmer was also added for use in extreme cold.

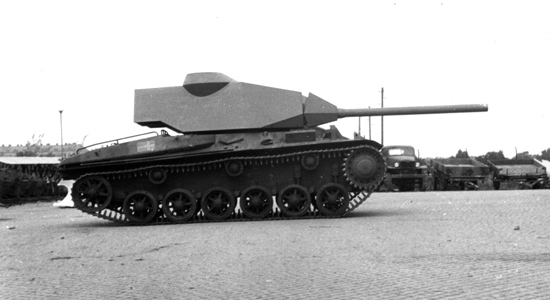

An early concept design for the M/42 Valkosusi, later to be substantially modified as the design process continued….

Overall, the end result weighed in at just 30 tons, with a powerful engine giving a projected top speed of 35mph and with substantially widened tracks giving low ground pressure (a particular concern for snowy or swampy conditions), the new tank promised good off-road mobility, good speed and had reasonable armor protection. The welded armour was rather thicker than its predecessor (although crews would come to regard it as too thin), offering adequate protection to the crew without being excessively heavy (the designers had intentionally traded off protection for speed). The design was simple and straightforward, making it cheap and fast to build – and to achive this, numerous simplifications had been made to the design. It had also been designed to rapidly replace the Patria M/38 Sotavaunut on the Patria assembly lines at Tornio. On paper, at least, Patria had produced a very capable armoured fighting vehicle. A wooden mockup of the Patria M/42 Valkosusi was constructed in tandem with the design and presented to the Review Committee on 29 April 1941.

One of the first Patria M/42 Valkosusi tanks to come of the production line being road-tested in 1942

One of the first Patria M/42 Valkosusi tanks to come of the production line being road-tested in 1942

(Author’s note: in terms of general size, think Stridsvagn 74 bulked up a bit to around the size of the Panther more or less but with a lower profile – not being a Photoshop expert I’m using photos of Panthers & Stridsvagn 74’s so forgive any visual discrepancies – but you should get the general idea)

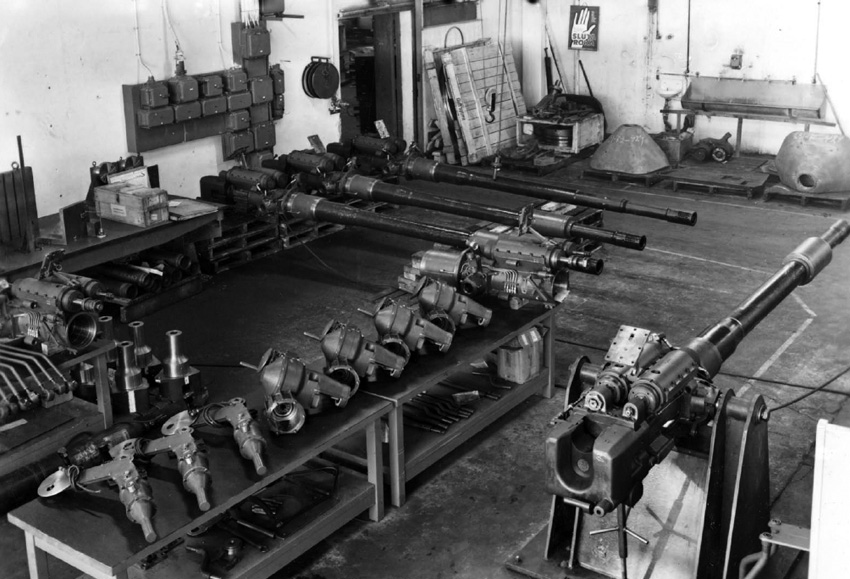

The Patria M/42 Valkosusi’s Main Gun

The gun that gave the Patria M/42 Valkosusi its punch was a rather more modified version of the Tampella-Bofors 76mm that gave the M/39 Panssarinhävittäjä its firepower. In the Winter War, the firepower this gun gave the Finnish Army was devastating. By 1942/43, it was rather less so, but this would be restored with new ammunition, as we will see.

The main gun proposed for the M/42 Valkosusi was a Škoda/Tampella engineering team modified version of the Bofors 76mm in use on the M/39 Panssarinhävittäjä. The gun was the same, the main modification consisted of making the gun fully automatic with a drum feed capable of 15 shots per minute and using a new type of armour-piercing ammunition. The long barrel and large propellant charge for the new ammunition to be used gave a very high muzzle velocity, a flat trajectory and excellent armor-piercing qualities. The flat trajectory also made hitting targets much easier, since accuracy was less sensitive to errors in range estimation and increased the chance of hitting a moving target, though these same attributes made the gun a poor fire-support weapon using HE ammo. Indeed, the Valkosusi’s 76mm gun had more penetrating power than the main gun of the Tiger I heavy tank, the 8.8 cm KwK 36 L/56. The AP-T projectile used initially had an overall weight of 7.2 kg and a muzzle velocity of 925 m/sec.

Average penetration performance established against rolled homogenous steel armor plate laid back at 30° from the vertical was:

- 100 m: 138 mm

- 500 m: 124 mm

- 1,000 m: 111 mm

- 1,500 m: 99 mm

- 2,000 m: 89 mm

To compensate for the wear of such rapid fire, a special compressed-air device had been designed which would clean the barrel after every shot. The weight of the gun, with it’s long barrel, was balanced by the rearward extension of the gun turret with added ammunition storage in the rear of the turret. The autoloader was proposed so as to ensure that the high velocity 76.2mm gun could fire so much faster than Russian / German weapons that an enemy target could be overwhelmed by the sheer volume of fire. On the other hand, this could also be somewhat of an issue as the main gun’s high rate of fire could use up all the ammunition in the autoloader (20 rounds in two bins of 10 rounds each) in less than two minutes. The tank itself would hold only 137 main gun rounds and given the high rate of fire, this could easily be expended in just a few minutes of combat. Also, reloading the autoloader could take up to 15 minutes if all rounds had been expended.

Debate on this subject was considerable. With the autoloader, 15 rounds per minute could be fired, while in manual loading, a rate of firing of around 8 rounds per minute could be achieved under favorable conditions with an experienced crew (one round each 7.5 seconds). There’s a considerable choreography involved in a manual reload – imagine that the loader would have to, in the confines of the turret and hull, under combat conditions, possibly while moving across country, reach to the rear stowage, pull out a 11 kg round from a magazine with one hand, get a grip on it, then turn so he could load the round and push it in. Getting to the reserve rounds under the floor and in the sponsons also required some intricate dance steps as the loader moved around to get the rounds.

However, this rate of fire would drop considerably under combat conditions and as the crew became increasingly fatigued. There was also of course the question of target acquisition. And then of course, after continuously firing rounds from tanks, after you get about 15 -20 shell casings laying/bouncing around/etc. on the floor, it gets really difficult for the loader to load more rounds and the turret to move or the gun to recoil safely, so there would have to be a pause just to clear the turret. But even at 8 rounds per minute the emptying of ready ammo racks and the obstruction of empty shell casings prevents tanks from sustaining this rate for any length of time. While the autoloader potentially enabled one crew member to be removed, reducing the crew from 5 to 4, a further drawback was seen as being that while replenishment of ammunition for the autoloader could be done from inside the tank, a complete reload of both bins generally took approximately 15 minutes.

The Patria M/42 Valkosusi’s Main Gun was in fact one of the most powerful tank guns of World War II, due to the large propellant charge and the long gun barrel, which gave the round a very high muzzle velocity, a flat trajectory and excellent armor-piercing qualities.

The review committee took one look at the autoloader proposal, viewed the risk as far too high and in an unusual example of Finnish verbosity, took the designers to task for a “dangerously high-risk proposal”. The Finnish equivalent of a shit-storm erupted, with the two opposing viewpoints being put forward at length. However, Škoda and Tampella had already worked together to produce a working prototype and this was satisfactorily demonstrated. Tampella also had considerable prior experience with autoloaders from 1938-39 with the autoloaders designed and developed for the Wihuri ground-attack aircraft with their nose-mounted magazine-fed 37mm anti-tank gun. Extensive trials of the 76mm autoloader were carried out. The improved 76mm used a more powerful charge which allowed it to penetrate 138 mm (of RHA sloped at 30 degrees) at 100 m and 111 mm at 1000 m, which was considered excellent. This gun gave the Valkosusi a firepower advantage over the Russian T-34 (the key design objective), although the muzzle flash due to unburnt powder from the increased charge could leave crews momentarily blinded after firing. The blast also kicked up dust from the ground and often obscured vision for further firing.

The addition of a muzzle brake solved this problem by directing the blast sideways (with the added benefit of substantially reducing recoil. The “improved” Tampella-Bofors 76mm also featured a gyroscopic stabilized gun and sight. The stabilization was only in the vertical plane, as the mechanism could not slew the turret. The stabilizer was sufficient to keep the gun within 1/8th of a degree, or 2 mils while crossing moderately rough terrain at 15 miles an hour. This gave a hit probability of 70% on enemy tanks at ranges of 300 to 1200 yards. The utility of the stabilization is debatable; with some Finnish tank crews saying it was useful for its intended purpose, others only used the sights for stabilized viewing on the move. Some Finnish Army tank crews disabled the stabilizer.

In the event, after considerable and very heated debate, it was decided to proceed with the autoloader in production as the advantages in combat were seen to outweigh the disadvantages. The 76mm autoloader gun went into production in time to be used for the first Valkosusi’s to roll of Patria’s Tornio production line. The Valkosusi’s 76mm main gun was in fact one of the most powerful tank guns of World War II, due to the large propellant charge and the long gun barrel, which gave the round a very high muzzle velocity, a flat trajectory and excellent armor-piercing qualities.

Standard AP-T ammunition was manufactured by Ammus Oy, but going into 1944, the tanks were also supplied with a white phosphorus shell intended for use as an artillery marker to help with targeting. Once the war against Germany started, Valkosusi tank crews quickly discovered that the shell could also be used against the Tiger and Panther tanks (and Russian T34’s for that matter) — when the burning white phosphorus adhered to enemy tanks, their optics would be blinded and the acrid smoke would get sucked inside the vehicle, making it difficult or impossible for the crew to breathe. This, and the fear of the fire spreading inside the tank, would sometimes cause the crew to abandon the tank.

In its final design iteration as production commenced, the Patria M/42 Valkosusi (“White Wolf”) weighed 30 tons, was powered by a 450-horsepower Finnish-manufactured Hispano-Suiza engine giving a maximum road speed of 35 mph and a range of 250 miles. With a crew of 5, it mounted the Tampell-Bofors 76mm main gun with a 20 round autoloader, 2 x 7.92mm machine guns and an external Lahti 200 cannon. The M/42 Valkosusi retained some of the design features of the earlier Patria M/38 Sotavaunut and the Sotavaunut’s immediate ancestor, the Czech LT35, primarily centered around the chassis and torsion bar system and the general “look” of the hull, although overall size had increased considerably to around the same dimensions as the German Panther.

Patria M/42 Valkosusi Production

The first mild steel prototype was produced by April 1941. An extensive and detailed review over the summer of 1941 was followed by further design modifications and the production of two further prototypes for August 1941, only one of which was fitted with a turret. The three prototypes were extensively and exhaustively tested and proved prone to a number of technical problems which were worked on. Likewise, many modifications were made to the interior layout, including much improved ergonomics. Nevertheless, the early consensus was that, even though fixes were needed for the problems identified, the new design had surpassed design specifications and expectations.

In June 1941, the Germans launched Operation Babarossa, the attack on the Soviet Union, an event that the Finnish military had been expecting for some time based on intelligence reports. The Finnish military had been partially mobilized over April and May 1941 in expectation of such an attack as at this point, the Finnish government and military command trusted neither the Soviet’s nor the German’s to respect Finland’s neutrality. Both Germany and the Soviet Union placed ongoing pressure on Finland, both economic and political, covertly and overtly, but Finland was determined to remain neutral. Without going into any further details at this point in the narrative, the outbreak of open war between Germany and the USSR resulted in a further large-scale mobilization of the Merivoimat and Ilmavoimat together with the Armeija. At the same time both Germany and the Soviet Union were repeatedly given notice of Finland’s intent to maintain its neutrality at all costs – a declaration that both sides reluctantly respected given their earlier encounters with Finland.

A view of the prototype from the rear: a single prototypes was also constructed on an M/38 Sotavaunut chassis with a wooden mock-up turret and gun.

The outbreak of open war gave an added impetus to the drive to re-equip Finland’s armoured units and in July 1941, the Army placed an initial order for 400 M/42 Valkosusi’s (as the new tank was now officially designated) to be manufactured in 1942, while a further 750 were to be completed over 1943. Patria M4/2 Valkosusi production commenced in March 1942 after an increasingly frantic re-jigging of the production lines was finally completed. As the M/42 had been designed very specifically to rapidly replace the M/38 Sotavaunut on the assembly lines at Patria, the changeover moved ahead rapidly, actually managing to come in 4 weeks ahead of the targeted completion date – a miracle of sorts for almost any engineering project. Patria had taken advantage of the new design to streamline and improve workflow and production techniques in light of experience gained with the production of the Sotavaunut M/38 and the M/39 and manufacturing efficiency had been very considerably improved.

Potential bottlenecks existed with four major components – steel, suitable engines, the Tampella-Bofors 76mm main gun and the turrets. Without adequate supplies of these, production in suffient quantity would prove a challenge, as had occurred with the Sotavaunut M/38. The new M/42 Valkosusi was a formidable design, but with war between Germany and the USSR already underway and the fighting taking place close to Finland’s borders, there was an urgent need to introduce the M/42 into service regardless of obstacles.

The first bottleneck, steel, was addressed through the simple expedient of increasing the output of rolled plate steel from the Tornio Steel Mill. Casting of the tank hulls had been considered, and certainly by 1940 the Tornio Mills could have been used to produce large cast components. Castings, though, have certain inherent disadvantages. No matter how metallurgically sophisticated a nation is, the physics dictates that grain orientation cannot be controlled, and grain growth is mostly uncontrollable in large castings. Thus even the most elegant tool steel alloys are not particularly strong as raw castings, without a further hardening process to make a fine grain structure. Casting’s main advantages, once the tooling is built, are production rate and lower (not higher!) technological requirements. A casting facility–especially one that works with simple alloys–can be nothing more than a big building, an overhead crane and a furnace.

Rolled plate, on the other hand, may not be perfect, but it offers fairly good and consistent grain size, work hardening, and especially grain orientation. Welding of fabricated plate sections, if done properly, does not compromise these advantages. The gains from plate’s metallurgical advantages more than offset the small trigonometric differences in effective thickness from small angles of incidence of shell impact against angled sections of cast hulls and turrets. Sophisticated heat treating can be combined with rolling to make very strong steel. But good rolled plate requires a very, very expensive and complicated mill. Fortunately, the Tornio Steel Mill had been built in the mid-1930’s with this kind of high quality rolled alloy steel output in mind and by reducing exported amounts, sufficient rolled plate steel was available for M/42 and M/39 production.

Rolled armor is essentially cast armor which has been further worked and shaped, which aligns the grain structure which increases ballistic strength. Rolled steel armor is made by first pouring molten metal into molds and allowing it to cool and solidify into ingots. These big barrel-shaped pieces which come out of the molds are then pounded with hammers (BIG hammers) to form billets, which are then rolled at the rolling mill to become slabs, which can be sized in thickness to fit the tank design. They are flame cut to the profile of the desired tank part, then heat treated, then welded into the tank. Cast steel armor components bypass all that working, and are made simply by pouring molten metal directly into tank component shaped molds. They are removed from the molds, rough spots, risers and gate marks ground off, and heat treated. Then they are built into the tank.

Given their small manpower pool and the need to keep casualties down, the Finns opted for better quality armour plate albeit at a higher labour cost per manufactured tank. Very good armor may deliver three or four times the performance, inch for inch, of the best possible homogeneous casting and this was factored into the alloy steel specified for the M/42’s construction. The flexural strength and notch sensitivity of the metal are perhaps the most important characteristics that distinguish sophisticated fine-grained differentially cold-rolled high-alloy plate, with not only a hardened face but maximum toughness of the plate core and maximum ductility of the inner face (to resist spalling), from homogeneous hot-rolled plate or varying-characteristic cast sections of carbon steel with no heat treatment beyond surface carburizing. Sophisticated plate depends on the flexural strength of the plate core to contribute its local stiffness to the spreading of the incoming shock wave over a larger area, so that the inner face will experience a lower peak force. Notch sensitivity, of course, is relevant to whether the inner face of the armor stays in one piece under dynamic conditions.

Good armor has a hard outer face to reflect as much energy as possible and spread the remainder over as large an armor area as possible; a high-strength tough interior to resist deformation and convert kinetic energy to heat; and a ductile inner face to resist spalling due to the propogated shock wave and local deformation. When an AP round hits it, the armor undergoes tremendous local heating. If the AP round overwhelms the armor and penetrates, a sizable amount of armor metal is typically ejected into the tank interior ahead of the penetrating round. That metal is at least very hot and sometimes molten. It can have a much higher velocity inside the tank than the remnant velocity of the penetrating round. This spray of liquid steel generally ignites whatever is flammable. Also, having lost much of its kinetic energy penetrating the first armor surface, the projectile is likely to bounce off the inner face of the far armor surface and richochet around the interior to the detriment of the occupants within.

Bad armor is hard through. When an AP round hits it, a few large chunks of armor pop inward to make a hole a bit bigger than the diameter of the projectile. These chunks may initially be moving fairly quickly, but having broken out at relatively low force levels, they are probably barely warm. Thus their damage contribution is minimal. The projectile

itself, having lost little velocity, continues onward. If it richochets off the gun or a wall, it may lose all of its energy bouncing around tens or hundreds of times inside, but if it hits the second wall cleanly, it may break out another clean hole and exit. For a given incoming round, the odds are very much higher that bad armor will result in a penetration. The reason that the results of a good-armor penetration are so much more violent is that the armor died its own violent death trying to keep the projectile away from the crew. You’re much, much more likely to end up dead behind bad armor than behind good armor. The Tornio Mills manufactured good armour and in more than enough quantity to meet Patria’s needs.

The second major bottleneck was suitable engines. In the years leading up to World War II, as the need for armored vehicles was realized, designers in all countries were faced with the problem of how to power the vehicles, which weighed considerably more than the usual trucks that large vehicle engines were designed for. To solve this, they turned to using aircraft engines, which provided greater power-to-weight ratios and were more reliable than conventional inline vehicle engines available at the time. In this, the Finns chose to utilize the Finnish-manufactured Hispano-Suiza inline engines that were then being manufactured in increasing numbers.

For tank use the Hispano-Suiza had its supercharger, reduction gear, and other equipment removed from its camshaft, greatly simplifying its construction. It had cast, rather than forged, pistons, and was de-rated to around 600 bhp (447 kW), running on lower-octane petrol instead of high-octane aviation fuel. In addition, because weight saving was not so important for a tank engine, some of the Hispano-Suiza’s more expensive light-alloy components were replaced with cheaper, steel components in the “M39/M42” version. It was also envisaged that the tank engine would use some components rejected on quality grounds for the Hispano-Suiza aircraft engine, i.e. Hispano-Suiza scrap. In use as a tank engine, the Hispano-Suiza engine was very lightly stressed and reliable, and substantially increased the power available. The first Hispano-Suiza prepared for tank use was tried in a modified M/38 Sotavaunut in September 1941 at Tornio and proved more than successful. Further helping avoid any bottleneck, the Hispano-Suiza engines were reserved for M/39’s and M/42’s to be delivered for Finnish use.

Those M/42’s destined for Sweden were shipped without engines, turrets or guns. A similar approach to the Tampella-Bofors 76mm main gun and the turrets ensured that adequate supplies were available for Patria. This in turn enabled the production line to be maintained at full speed from the date of inauguration of M/42 Valkosusi production in early 1942 through to the end of WW2. And afterwards for that matter, as orders were placed for the re-equipment of the Armies of Finland’s close allies, in particular Poland and the four small Baltic States.

Once in service, the M4/2 Valkosusi reliability would prove to have benefited greatly from the detailed input into the requirements and design. Indeed, in tests against US-supplied Sherman tanks, Russian T-34’s from the tail-end of the Winter War and, later, on captured German Panther and Tiger tanks, “…the Valkosusi was faster than all the others, both across country and on the highway and could make sharper turns. It was also the better hill climber and could maneuver nicely over ground where the US and German tanks, and at times also the Russian tanks, would bog down…..” Advantage had also been taken of many features developed in the US in the 1930’s of which the Finns had become aware when working to procure arms and equipment over the course of the Winter War.

The first M/42 Valkosusi rolled of the Patria production line in early April 1942, with the 200th completed in mid-November of the same year. Production continued, with the Patria line working at full capacity as the Soviet Union fought on against the Germans, a battle which the Finns watched with something close to paranoia, fearing that one side or the other might attempt to drag them in. Ongoing attempts through this period to put in place a formal military alliance with Sweden were rebuffed, with the Swedish Government continuing to regard Finland’s domestic politics and “overtly and aggressively militaristic stance” with great suspicion. Finland’s public commitment to the cause of Estonia also caused the Swedish Government concern, as they wished to remain neutral and not be drawn into a war with either the USSR or Germany by the “unsteady and adventurous” Finns. Finland was now perhaps even more isolated than she had been at the time of the Winter War, although now the two totalitarian behemoths were warring on Finland’s very borders.

Standard practice when moving the Patria M/42 Valkosusi cross-country in non-combat situations was to fully elevate the gun, or reverse the turret – here, reversed and locked down

By January 1943, on average approximately 25 M/42 Valkosusi’s per week were being produced and sufficient were on hand have completed the re-equipment of the 21st Panssaridivisoona. Unfortunately for the Finnish Army, Finland did require export income and Sweden would again apply pressure to the Finnish government to export weapons to Sweden. This caused a considerable debate within the Finnish government, particularly as Sweden’s defence spending and investiment in defence manufacturing infrastructure was nowhere near the level that Finland maintained, at great cost, throughout the years of WW2. Despite this, from April 1943 on, almost half the Valkosusi production was exported to Sweden, albeit without the turrets and guns, which were produced in Sweden (as they had been for the Swedish Army’s M/38 Sotavaunut’s).

Finnish Army M/42 Valkosusi’s in cover outside a Latvian village during the advance south down the Baltic, May1944

This considerably slowed deliveries of the Valkosusi’s to the Finnish Army through 1943 and it was only by March 1944 that the 22nd Pansaaridivisoona found itself fully equipped at last with the Valkosusi. The 23rd had to make to with lend-lease Shermans supplied by the United States. A great deal of ill-feeling was generated by this Swedish demand, particularly as the hundreds of Valkosusi’s supplied to Sweden would never see battle. As one Finnish panssaari officer put it succinctly in mid 1944, shortly after the landings in Estonia, “the damned Swedes are protecting themselves yet again at the cost of the lives of Finnish soldiers.” This ill-feeling was somewhat offset by the full Division of Swedish volunteers who were now fighting within the Finnish Army.

After the Patria M/42 Valkosusi began to enter service in 1942, some further problems were identified. One was the length of the 76mm main gun barrel. Not unexpectedly, as with the Patria M/39 Panssarinhävittäjä, it was necessary for crews to be careful not to plough the gun barrel into the ground while traveling cross-country or in combat. A Finnish tank crewman later commented: “…the tank gun could easily dig into the ground in the smallest ditch. If you fired it after that, the barrel would open up at the end like the petals of a flower.” Standard practice when moving the M/42 Valkosusi cross-country in non-combat situations was to fully elevate the gun, or reverse the turret. On the other hand, none of the Valkosusi crews wished to trade off a lower velocity round for the convenience of a shorter barrel.

During the winter and spring fighting of 1944–45, the M/42 Valkosusi demonstrated a marked advantage over both Russian and German tanks in its ability to move easily and rapidly over deep mud or snow without bogging down, leaving even the renowned T-34 in its wake. Finnish experience through the 1930’s with operating heavy logging equipment under similar conditions, and the resultant contribution to the M/42 Valkosusi design had paid off in spades. In terms of mobility, the Patria M/42 Valkosusi’s broad tracks, truly excellent suspension, low ground pressure and powerful engine gave it unparalleled cross-country performance while the tracks themselves were generally reliable and capable of running up high mileages before needing replacement. The powerful motor in proportion to overall weight resulted in a good turn of speed. Mechanically, the M/42 Valkosusi proved to be highly reliable; maintenance in the field was straightforward while the tank’s low profile was also a definite advantage in combat, as was the ability to depress the main gun, allowing the Valkosusi to “snipe” from cover.

In battle through 1944 and 1945, the M/42 Valkosusi generally proved superior to both the German tanks and, when called for (as happened on any number of occasions) Russian tanks. The Valkosusi was certainly far superior to the US-supplied Sherman’s; the American, British, Canadian and Polish armoured units fighting under overall Finnish Command on the Baltic Front over these years were generally envious of the superior Finnish tanks. This envy was no doubt further enhanced when the Finnish Army introduced its new High-Velocity Armor Piercing (HVAP) ammunition in May 1944 for the 76 mm gun, just in time for E-Day and the invasion of Estonia. The projectile contained a tungsten core penetrator surrounded by a lightweight aluminum body, which gave it a higher velocity and more penetrating power. The higher-velocity 76 mm gun and the HVAP round combination would give the Patria M/42 Valkosusi anti-tank firepower that would be superior to most of the German tanks they encountered through the remainder of WW2.

Agile enough for fast tactical relocation, reasonably armored and with excellent firepower, the M/42 Valkosusi has long been considered as contender for one of the best tanks of the WW2 years, a remarkable feat considering its origins in the mid-1930’s.

Pioneeri Variant

On March 29th of 1943, it was decided to produce a recovery version of the Valkosusi for use in the Panssaaridivisoona. In June of 1943, Patria produced the first 20 of a prototype series Pioneeri-Valkosusi which were turretless and heavily modified for engineering and recovery tasks. Production started on a small scale, mixed in with the main production run, from July of 1943. Production was intermittent with batches intermingled with the Valkosusi runs and various modifications were made during the production. Early versions were armed with a 20mm Lahti cannon and later on with twin 7.92mm machineguns as well.

The Pioneeri-Valkosusi was operated by a crew made up of a commander, a driver and a mechanic. It was fitted with a 1.5 ton lifting crane and other recovery/repair equipment (eg. a large shovel, a 40 ton winch, etc.), some of it specially designed. Overall, 97 were produced from June of 1943 through to March of 1945 and were spread across all 3 Finnish Panssaridivisoona, a part of the significant investment in tank recovery and repair units that the Finnish Army made – that paid off with disabled vehicles being repaired and returned to service more often than not. The Pioneeri-Valkosusi proved one of the best recovery vehicles of World War II and remained in use through to the mid 1950’s. Post WW2, numbers were manufactured and exported to the armed forces of Sweden, Norway, Denmark, Poland, Estonia, Latvia, Lithuania, East Prussia, North Germany and the Czech Republic.

The Patria Valkosusi – a brief post-WW2 history

While not directly relevant, I’ve included this as a post-script on the life of this historic tank, which, when it finally went out of production at the tail-end of the 1960’s, would close the book on a pedigree that went back to the early 1930’s and almost the first post-WW1 tanks.

Post WW2, the Valkosusi-I would continue to form the mainstay of the Finnish Army’s armoured units through the 1940’s and well into the 1950’s. An upgraded version with a 105mm gun, additional armour and a more powerful engine, the Patria M/52 Valkosusi-II, was manufactured and used by the Finnish Army as well as by the Polish Army and the Army’s of the four small Baltic States. Following the establishment of the Czech Republic in 1945, Škoda Works would be re-established and would soon go on to produce the Valkosusi-II for the Czech Army. Škoda Works and Patria would jointly export the upgraded Valkosusi-II (and the later Valkosusi-III) to Sweden, Norway, Poland, Estonia, Latvia, Lithuania, East Prussia and later on, to the armed forces of Northern Germany, Denmark, Israel and Spain as well as to some South American countries in small numbers.

Over the course of the 1950’s, Spain received a total of 389 M/52 Valkosusi-II’s financed by US Military Aid, which incidentally also funded the acquisition of the M/52 Valkosusi-II’s by Poland, North Germany and the four small Baltic States as part of the ongoing Cold War between the US and the USSR. In addition, both Finland and Škoda Works sold arms and tanks to Israel in the years after WW2. Even prior to the establishment of the State of Israel in May 1948, as the Haganah searched for weapons, its agents would establish ties with Finland’s Osasto Karhu, a department of the Etsivä Keskuspoliisi and it’s secretive and ruthless head, Esko Riekki. Working as he did directly for the President of Finland until his retirement in 1958, it can only be surmised that these sales had Presidential approval, although it must be said that Riekki was not noted for his deference to authority, even when serving under Mannerheim during the war years, nor was he noted for leaving paper trails.

While little or no documentation exists, circumstantial evidence does point to Riekki being instrumental in arranging the sale of 10 of the surviving Finnish Army Hotchkiss H35 tanks, together with a further 15 Renault R35’s and an indeterminate number of Sherman’s (of which the Finn’s possessed large stockpiles, many of them damaged but repairable; these Shermans were sold to Israel by the ton as “scrap metal”, hence the lack of specific numbers). Also sold to Israel as “scrap metal” were large numbers of WW2-era Soviet and German rifles, machineguns, artillery, tanks (including a number of T-34’s which the Finns “just happened to have lying around”) and assorted ammunition for which the Finnish Army had no need. While these were the only direct Finnish arms sales to Israel at this time, they were large in volume and came at a time when the Israeli armed forces needed every weapon they could lay their hands on.

Indirectly, the Israeli’s would go on to acquire large numbers of the M/52 Valkoinensusi-II’s from Škoda Works in the late 1950’s. As tensions had mounted with Eqypt through the early 1950’s, Israel had made an application (which was refused) to the US in 1955 to purchase 60 M47 tanks (and applied again in 1958, this time to purchase 100 M47 tanks but the answer was again the same). Škoda Works had by this time fulfilled all extent orders for the Valkoinensusi-II’s and, looking to keep the production line going, was in search of orders. An approach by the Israeli’s met with a positive response, the Czech government raised no objections (and indeed, facilitated the order in every way possible). The end result was that an immediate order for 230 M/52 Valkoinensusi-II’s was closed, with an initial shipment of 100 taken from the Czech Army’s reserves (to be replaced with new tanks).

Thus, at the time of the Suez Crisis in 1956, the main IDF tanks were the French-supplied AMX-13, the M/52 Valkoinensusi-II’s and WW2-era US tanks. And finally, in the early 1960’s, Israel signed a deal with Škoda Works for the purchase of 150 M/60 Valkoinensusi-III tanks. A further 120 were ordered in 1966 and delivered over the next two years. The Valkoinensusi-III incorporated a number of modifications including a new 553hp gas turbine engine, a Tampella-Skoda 105mm L/60 main gun with an autoloader allowing a rate of fire of 15 rounds/minute and a crew of 3 (driver, gunner, commander). There was also provision for an extra crew member, a rear driver/radio operator, who faced the rear of the tank equipped with a complete setup for driving. This allowed the tank to be driven backwards at the same speed as forwards, keeping its frontal armour pointed at the enemy.

The Patria and Škoda Works partnership would sell Valkoinensusi-II and III’s in small numbers elsewhere but by the early 1970’s, the cost of developing a new Main Battle Tank far exceeded the financing available to either Patria or Škoda Works and, without government backing or guaranteed orders in large volume, both companies withdrew from the MBT market, bringing the end to an era.

Previous Post: The Enemy: Soviet Tanks of the Interwar Decades

Next Post: Fortifying the Isthmus – early fortifications and the geopolitical position

References and thanks: a special mention of http://www.ointres.se/strv_74.htm for many of the photos re-used.

Copyright secured by Digiprove © 2014 Alternative Finland

Copyright secured by Digiprove © 2014 Alternative Finland