The Emergency Construction of the Lyngenfjord Highway – 1939

As a practical illustration of the experience within Finland that existed within the logging and construction industry at the end of the 1930’s, the construction of the Lyngenfjord Highway is an outstanding example. Within the context of the entire Second World War, perhaps the only two comparable engineering projects were the constructions of the Alaska Highway and the Burma Road – both of which came well after the construction of the Lyngenfjord Highway. The later Petsamo Highway, built in 1940, while a major engineering feat, was based on an existing highway and while it was completed rapidly in light of the German invasion of Norway, there was not quite the same groundbreaking factor involved.

The construction of the Lyngenfjord Highway as an emergency measure had been sparked off by the Munich Crisis of September 1938. This and the subsequent dismemberment of Czechosolvakia, the ineffectiveness of the League of Nations and the appeasement of Germany by France and Britain at the cost of the independance of a small European state had come as a shock to many in the Finnish Government. To others, it was a vindication of all they had been warning about for so many years. Munich also unfortunately resulted in the abrupt termination of a number of as yet unfulfilled orders for military equipment that Skoda was in the process of completing for the Finnish Army, chiefly Artillery pieces – orders that Germany simply took over without compensation. Finland’s protests were ignored and while Germany continued to be a major trading partner for Finland, the actions of the German government did nothing to improve the Finnish-German relationship, which was in any case at best peripheral for Germany.

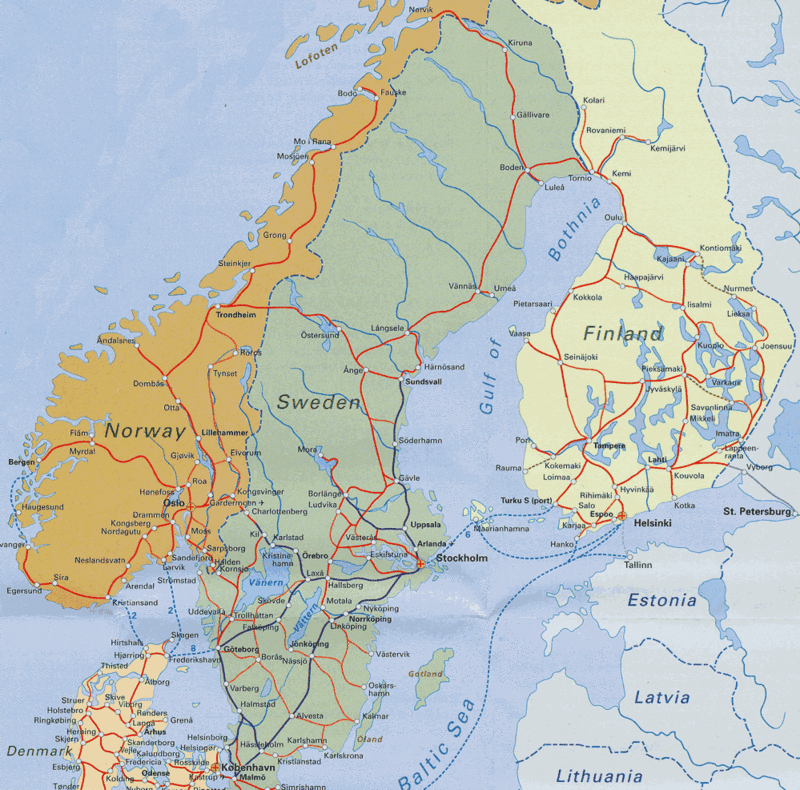

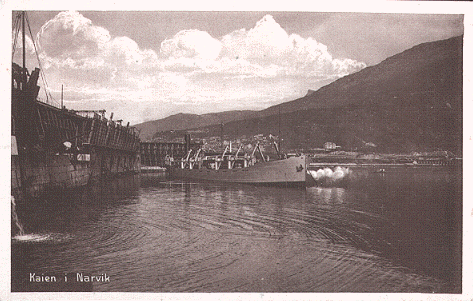

The Government of Finland responded in a number of different ways – these we will cover in later posts. Suffice it to say that in the event of a major European war, as in WWI it was expected that shipping traffic to and from the Baltic would be cut. Thus it was planned that in the case of a global conflict or of a war between Finland and the USSR, the majority of the fast cargo ships would be sent out of the Baltic in order to operate to and from Swedish and Norwegian ports. As port capacity of the Swedish port of Göteborg and the Norwegian port of Bergen would almost certainly be hard pressed, the basic wartime shipping contingency plan was to utilize Narvik for emergency import and export tasks. The planned use of Narvik was facilitated by three factors: First was that congestion in Narvik had decreased due to the shifting of iron ore transportation to the Swedish port of Luleå, and secondly, due to the fact that Sweden, whose major industries and population were concentrated in the south, was unlikely to fully utilize Luleå port’s full capability. Third was the rail link to Narvik.

The Scandinavian Rail Network

Despite disparate railway gauges between the Swedish and Finnish rail networks (1524mm for Finland and 1435mm for Sweden) this was the only really viable alternative link that was usable for major volumes of freight – and this was also a bottleneck in a crisis situation. Firstly, the 103 mile long line from Boden in Sweden north to Haparanda (and then a further 1.9 miles from Haparanda to Tornio in Finland) was only a single track line. This railway was built in several sections over the course of 17 years with first segment from Buddbyn to Niemisel completed in 1900, followed by the segment Niemisel to Morjärv in 1902.

The railway did not reach Lappträsk until in 1910, and the Swedish–Russian border at Karungi on the west bank of Torne River was not reached until 1913. Karungi was to become a junction, and the railway reaching northward to Övertorneå was not build until 1914, followed by the southern Karungi to Haparanda line in 1915. The only open railway connection between Germany and Russia during World War I ran through here. Lenin traveled here in 1917 to organise the Russian Revolution. The rail bridge over the Torne River between Haparanda and Tornio was only placed in service in 1919. Before that passengers had to walk or use horse carriages the short distance between the cities. The Haparanda station building was finished in 1918, and was sized based on the traffic during the war. All international travelers had to change trains here because of the break-of-gauge, and had to go through passport checks.

Haparanda Station, Sweden

During World War I in 1914-1916 Tornio had experienced an unprecedented period of bustling trade. As soon as the war started Russia’s usual foreign trade access points through the Baltic Sea and the Black Sea were closed off. As Russia’s wartime economy was dependant on imports, trade routes had to be changed to alternative paths. Goods started to be transported via Sweden and Norway to Finland and onwards to Russia. Russian exports were partly also transported via the same route. As a large part of these goods passed through Tornio, since there was already a railway in place, the traffic conditions of the city were completely revolutionized. Tornio was not only important to the upkeep of Russia but in the war years it was a major transit point for Finnish foreign trade.

Even though Tornio was merely a transit point, this traffic left money behind in many ways and as a byproduct Tornio’s own commerce flourished. All major trading companies from the southern Finnish cities set up offices in Tornio to manage the transport of goods between Tornio and Haparanda across the border in Sweden. In Tornio many new companies were also established and there was an unlimited amount of work for them. The transport companies hired all available horses and freight costs were high.

The Haparanda-Tornio Rail Bridge (note the different rail gauges – 1524mm for Finland, 1435mm for Sweden – as late as 1915, Sweden’s fear of the old enemy Russia was stronger than the economic reasons to establish a direct rail link).

The largest such company, Karl Boström, quickly arranged a horse freight service via Kilpisjärvi to Lyngenfjord in Norway (and it was recent memories and experience with this link that gave rise to the Lyngenfjord Highway proposal of the late 1930’s – this was not a venture into the unknown, it was a route that had been heavily used only 20 years earlier). This unending stream of transport saw its height in 1916 while in the year of the revolution in 1917 the trade to Russia dried up. Even so in the early spring of 1918 Tornio was still the commercial gateway to “white” Finland. Many refugees as well as prisoners of war who had escaped from prison camps also travelled through Tornio in both directions. The border at Tornio also became an exchange point between Germany and Russia for the exchange of prisoners and the wounded.

A railway between Tornio and Haparanda would have assisted greatly in the transportation of goods over the course of WW1 but the link was not completed until 1919. Post 1919, exports through Tornio to Sweden and via Scandinavia to the rest of the world would continue to be remarkably extensive and importing businesses also started to take advantage of the railway link. There were some hindrances – the different rail gauges between the two rail networks meant that onward freight in both directions needed to be cross-loaded, and in the early 1920’s, this was a labour intensive task. Logistical handling improvements speeded up this work and reduced the costs of cross-loading substantially (as was covered in one of the very early posts).

However, the single line link WAS a logistical bottleneck and there was also a potential political problem in that Sweden could not be relied on to support Finland unequivocally should a war break out between Finland and the Soviet Union. As we will cover in a later Post, from the mid 1920’s onwards, Finland had continuously worked to try and build a defensive alliance with Sweden. These efforts however had not had any success – Sweden was cautious with any action that had the potential to bring the country into a conflict wit the USSR (old fears of Russia were always close to the surface). There was an additional factor, in that the leftist governments of Sweden were suspicious of the Finnish governments (there was no great love for the Finnish conservative coalition governments of the 1920’s, and even the “Red Earth” coalition was looked at with suspicion).

Thus, there was a continuing “risk factor” that in a war between Finland and Sweden, Swedish support might be non-existent and pressure on Sweden from the USSR might result in any links to the external world through Sweden also being cut. Thus, while the rail route to Narvik was a likely contingency route, it was not by any means guaranteed. Likewise, the rail link to Narvik itself was a bottleneck. Perhaps a little more description of this link is in order before we examine the Lyngenfjord Highway Project in detail.

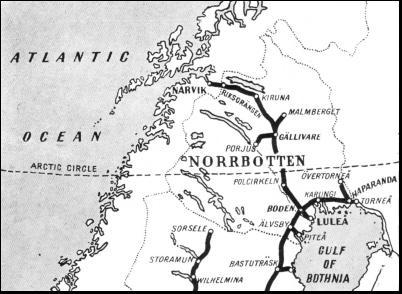

The Railway to Narvik

The Railway Line to Narvik

While Narvik is a town with a long history, it only really became important in the 1870’s, when the Swedish government began to understand the potential of the iron ore mines in Kiruna, Sweden. Some of the best iron in the world comes from Sweden. One of the most important iron ore districts of Sweden—the Norrbotten District— lies in the wild fastnesses of Lapland, beyond the Arctic Circle. The existence of the great Lapland ore fields was well known generations ago, but the iron workable in those parts had a high content of phosphorus, which made it useless in the smelting methods used in days gone by. Lapland ore consists of magnetite (magnetic oxide of iron), and has an iron content of 60 to 65 per cent, this varying according to the amount of phosphorus in the ore. The greater the phosphorus percentage, the less is that of iron. Iron to-day dominates the region that stretches in an attenuated form from the Gulf of Bothnia in Sweden to the coast of the North Atlantic at Narvik, in Norway.

Once that district was remote and as little penetrated as was the Hudson Bay area in Canada. To-day, electric trains run across and through the mountains, and men have built busy industrial towns in the middle of the primeval forest. Iron was the sole reason for these developments. Away from the beaten track—that is, the iron ore districts and their traffic artery—Lapland is still virgin country. Though the smelting and conversion to steel are not carried on in the Norrbotten District, the Basic Bessemer process was the immediate cause of the development of that district. In his original process, Sir Henry Bessemer was obliged to avoid using phosphoric iron because it was unsuitable for his original converters. In 1878 the engineers Thomas and Gilchrist, faced with this disability of the Bessemer process, conceived the idea of lining the furnaces or converters with magnesia and lime where phosphoric iron was to be treated. They bonded the mixture together with tar, or similar material containing little silica, and added lime to the metal during the blowing process. The magnesian limestone mixture absorbs phosphorus out of the molten iron as long as oxidization is continued, as, for example, by the frequent addition of ore containing iron oxide. Thus the introducers of the Basic Bessemer process assured the future of the Lapland ore fields.

The ‘eighties of the last century saw the first developments in the opening up of the Lapland iron ore district. Close to Gallivare, nearly fifty miles north of the Arctic Circle, rose the great Malmberg, 2,026 feet high and described as a “solid mountain of iron.” “Reef” would, perhaps, be a more correct term, though the name Malmberg means “iron mountain.” This huge reef, between three and four miles in length, consists chiefly of bright specular iron (crystalline sesquioxide of iron) mixed with magnetic oxide of iron. The Malmberg, however, could not be worked without a means for carrying the ore away to the sea for shipment. Obtaining iron ore from Kiruna had one significant problem in that there was no suitable Swedish port. The nearest Swedish port, Luleå, had limitations. It was covered with ice all winter, it was quiote a distance from Kiruna, and it could service only medium-sized bulk freight vessels. Of roads in Swedish Lapland there were none worth the name. None of the country’s huge rivers, with their rapids and falls, could support shipping, and iron ore could not be carried down these swift rivers in the same way as timber. Realizing these problems, a Swedish company (Gällivarre Aktiebolag) decided to build a railway to Narvik, through surroundings and into latitudes where the locomotive had never before been imagined, as the port there is ice-free thanks to the warm Gulf Stream, and is naturally large, allowing ships of virtually any size to anchor. Therefore, Narvik was established as an all-year ice free port for the Kiruna and Gällivare iron mines.

In 1887 work was begun by British engineers on the railway from Lulea, on the Gulf of Bothnia, to Gallivare and Malmberg. This line was owned by the North Europe Railway Company and was promoted by capitalists in England. The railway to the Gallivare area was opened in 1888, and with its inauguration the mining engineers were able to make a beginning. After the start made at Gallivare, the prospectors pushed on, still farther north, to the great ore reefs known as Kiirunavaara and Luossavaara. To reach these reefs the engineers had to carry their line more than 100 miles north of the Arctic Circle. They penetrated virgin forest and bare mountain-side until they reached the reefs. The main reef, Kiirunavaara, appears from a distance as a serrated mountain ridge and has a length of nearly five miles. The Luossavaara reef, besides being considerably smaller, forms the summit of a rounded hill. The three reefs already mentioned are estimated to contain at least a billion and a half tons of ore. It is probable that a great deal more remains for the prospector. In addition to these, there are lesser workings owned by the Swedish Government in Lapland at Svappavaara, Leveaniemi, Ekstromsberg and Mertainen.

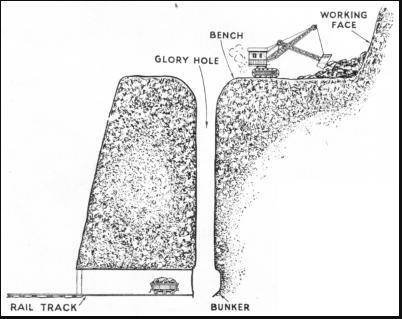

Dr. Hjalmar Lundbohm was the father of the Kiirunavaara workings and of the modern township of Kiruna which has sprung up beside them out of the northern waste. He saw his projects realized in the early years of the present century and to-day the community virtually founded by him is the largest in the whole of the Norrbotten District. In this district the mining engineers use the “open cut” system in attacking the great reefs at the Gallivare and Kiruna centres. This means that they quarry out the sides of the reef in terraces, or “benches,” as they are called, so that the mountain looks as if it has been cut into a series of enormous steps. The miners bore the face of the mountain with powerful rock drills and insert their charges. When a blasting operation is about to take place a siren is sounded and an observer sees figures on the face of the workings beginning to move away from the critical place. Again the siren sounds, a third time and a fourth. Finally another siren, with a deeper pitch, sends forth a long-drawn note as a last warning. Then the man responsible fires his charge. There is heard the deep, thudding volley of the charges, followed by the crash of falling rock.

THE GLORY HOLE of an open iron ore mine is shown in this sectional diagram

In adopting the open-cut system, the engineers had to evolve means of getting the ore quickly and easily away from the working face and into the trains which carry it off for export. This was done by making “glory holes,” as they are called in English-speaking countries. At ground level the men pierce the face of the mountain with a series of railway tunnels, each terminating in a dead end. This dead end contains a spacious ore bunker, from which the excavators bore what is known as a “raise,” straight upwards through the rock until they break ground on the surface of the bench overhead. The upper end of the raise they widen out in a funnel formation, so that the glory hole acts as a huge chute, with a hopper at the top. The miners clear away the ore from the face of the cliff and pass it into huge crushers which reduce the pieces of ore to a size suitable for shooting down the glory hole. Small tram-roads assist in carrying material on the benches and huge power-driven shovels do the lifting and dumping.

This entire operation of blasting, crushing and transporting to the tops of the raises is known as milling. While the milling is going on up above, the men at work in the bunkers down below are busy. As the ore falls into the bunkers, it is held back by strong gates, from which the loaders draw it off, finally shooting it into the waiting railway wagons in the tunnel. The open cut system of mining is a method of some antiquity. Miners knew it long before they knew the deep shaft, the high-speed winding engine or galleries situated about a mile below the surface of the earth. In Germany all classes of mining are known as Bergwerk, or “mountain working” and, on considering the open cut system, we see how the early mining engineers came to use this term. When the first pioneers came to the Lapland ore fields, they saw that the open cut system would be the one to employ on the vast reefs round Gallivare and Kiruna. Where it can be practised the system eliminates many difficulties with which the builders of underground workings have to contend. The open benches cannot be flooded nor can they catch fire. The dangers from falling rock, though they exist, are far less than in the vast systems of underground galleries common in Great Britain and elsewhere. The ore is on the surface, waiting to be taken away.

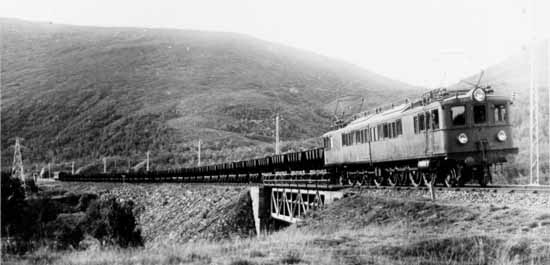

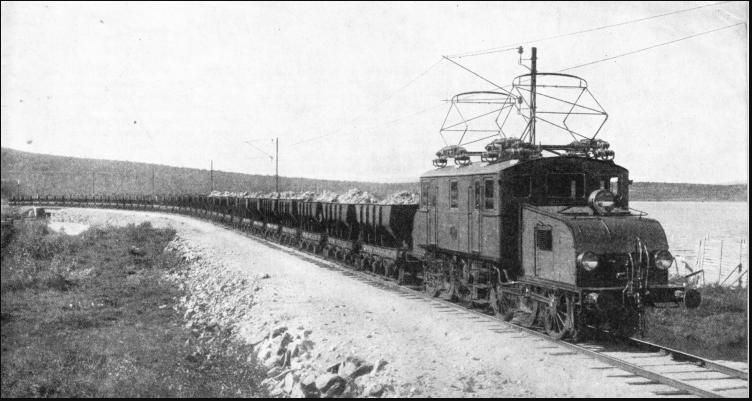

Iron Ore Train on the Narvik LIne

The township of Kiruna is a good example of town planning. For his site Dr. Lundbohm took a relatively low hill and arranged the roads of the residential parts as a series of concentric rings girdling its lower slopes. On the summit he set the site for the public buildings which to-day consist principally of a bank, a post office, a church and a cinema. With this nucleus it is an easy matter to expand the town without destroying its symmetry and initial layout. The great Lapland Ore Railway is the traffic artery without which the whole industry in these remote parts would be at a standstill. When the old North Europe Railway Company began work on its first section between Gallivare and the coast, it had a relatively easy task before it. Sweden has a generally easy slope down towards the Baltic and the Gulf of Bothnia from the central Scandinavian mountain chain, which divides the country from Norway on the west. In carrying their line up from the coast, the railway engineers took a fairly straight slant across this gradual inclination. The gradients were relatively easy and the engineers encountered none of the difficulties that were keeping their colleagues at bay in Norway. After a time, however, the private company gave place to Swedish Government interests.

Another Iron Ore Train on the Narvik Line

In the beginning of the present century the railway engineers completed their line over the great Lapland mountains, by dint of superhuman work with rock drill and blasting charge. In 1884, Gellivare Aktiebolag (taken over in 1889 by LKAB) was granted a concession for mining in Malmberget. Four years later, the first part of the Ore Line, from Malmberget to Luleå, was completed. In 1889, the mining company filed for bankruptcy, and the Government of Sweden bought the line for 8 million Swedish krona, half the original investment cost. Construction of the Ore Line and Ofoten Line from Gällevare to Narvik started in 1898 and was completed in 1902. The Norwegian section of the Line was called Ofotbanen (the Ofoten Line) and was a 43-kilometre (27 mi) railway line running from the Port of Narvik to Riksgränsen on the Norway–Sweden border, where the line continues as the Ore Line via Kiruna and Gällivare to Luleå.The Ofoten Line was single track, electrified at 15 kV 16⅔ Hz AC and with seven stations. Construction of the Ofoten Line started in 1898, simultaneously with construction work on the Ore Line from Riksgränsen to Kiruna.

Snow Plough on the Narvik Line

The year 1902 saw the first, ore trains running through from Kiruna to Narvik allowing iron ore to be hauled from the mines in Kiruna to the ice-free Port of Narvik. The Lapland iron industry was independent of the Lapland winter at last. But the opening of the through railway line did not solve the problems of the engineers responsible for the transport of the ore. Their walls, giant fences and snowsheds might ward off the devastating effects of sliding snow, but they had still the drifting snow to contend with. At first they adopted the same methods as are used in Great Britain on the exposed lines of the Scottish Highlands and on the Pennines. A locomotive would have a great prow-shaped plough built up over its buffers and smokebox; two others would be coupled up behind, and the three, thus armoured, would be sent at speed into the drifts. This method worked fairly well, but there was always an element of danger in it and it could scarcely be described as scientific. One day in the winter of 1904 a plough, thus driven by three locomotives, met with such resistance that all were thrown off the track.

Because of this accident, the Mechanical Engineer’s Department of the Swedish State Railways decided that the only way to deal with such a climate as that of Lapland was to adopt the rotary type of plough. Briefly, this consists of a huge multi-bladed wheel or rotor, with a central cutting boss, mounted on the front of a special railway van and turned by a powerful engine inside the van. With this appliance, those responsible for keeping the track clear are able to screw their way through the drifts instead of forcing through them. As the rotor turns, it automatically shoots the waste snow out at one side of the stout steel hood that covers it. The entire snow plough is propelled by an ordinary locomotive coupled up behind it. The ploughs, originally steam-driven, are to-day electrically operated. The Swedish State Railways’ engineers were the first to apply electricity as a motive power for snow ploughs.

Bjørnfjell Station, at 513 metres (1,683 ft) above mean sea level, in 1906

The original motive power of the Iron Ore Railway was steam. From the first, the Operating Department found that steam had its limitations. The steam locomotive is not an ideal form of power in exceptionally cold climates, and the winter temperature in the mountains of Lapland is often round about zero Fahrenheit. The engines, too, were of only moderate power, and at first it was normal for three to be requisitioned for hauling one ore train over the mountains, a wasteful and costly process, particularly in a country such as Sweden, which has few coalfields and has to import her fuel. Large engines were built in an attempt to reduce piloting and its attendant costs, but shortly before the war of 1914—18 the engineers of the Swedish State Railways decided that electrification would provide the solution of their traction troubles. Even this was not without its difficulties. They could not use conductor rails, which are most susceptible to the effects of ice and snow.

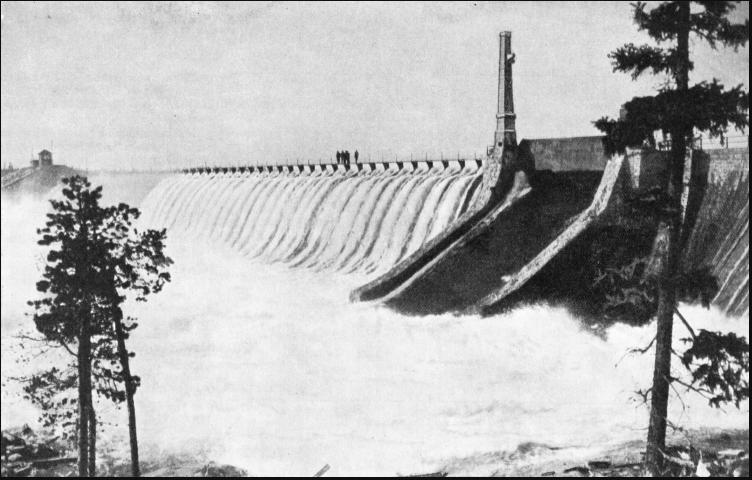

Lulea River Dam

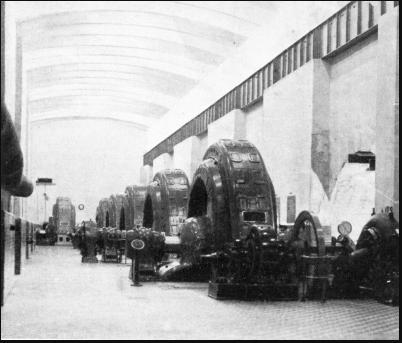

Having studied methods which were then being adopted in the Alpine countries, they decided to use the single-phase system, feeding current to overhead contact wires at 16,000 volts, 15 cycles. For the source of their energy they chose the Great Lulea River, near where it flows out of the Suorva Lakes on the first stage of its journey down to the coast at Lulea. They placed the hydro-electric power station at Porjus. As a protection against climatic conditions the machinery was installed in a hall 160 feet below ground. Porjus Power Station contains six single-phase generators for traction and power, one being held in reserve. The energy is generated at 4,000 volts, 15 cycles, but the transformers feed it to the overhead transmission lines at a pressure of 80,000 volts. Two main transmission lines radiate from Porjus to the fifteen sub-stations, where the current is stepped down to its final pressure of 16,000 volts. Of these lines one runs northwards and forks, sending branches to Kiruna and Tarendo, and the other southwards to the Gulf of Bothnia. A line of steel pylons carried the transmission fines of the Iron Ore Railway across 316 miles of bleak fells and deserted forests.

Porjus Power Plant Dynamo Room

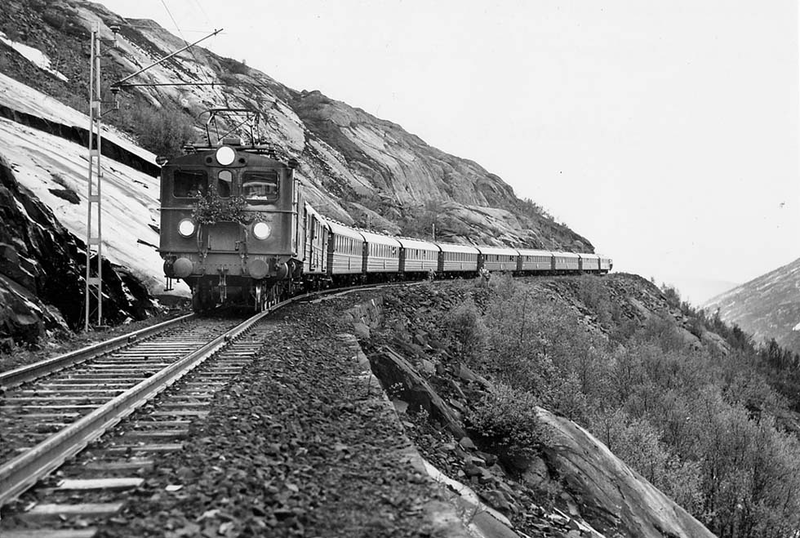

On 19 January 1915, the Ore Line between Riksgränsen and Kiruna was electrified. Until 1925, Swedish Oe locomotives were used. NSB decided to order two types of electric locomotive for the line: El 3 and El 4. El 3 was nearly identical to Oe and was a twin unit locomotive with a combined power output of 2,132 kilowatts (2,859 hp). Four twin units were delivered in 1925, and a fifth in 1929. The El 4 locomotives were longer and more powerful, and operated as singles. Each single El 4 had the same power output as a twin El 3. Two units were delivered in 1926, two in 1928 and one in 1929. Operation and ownership of the Ofoten Line was held by the Norwegian State Railways. A plan for electrification of the Ofoten Line had been made in 1911, but not until 1920 did parliament approve the plans. Operations with electric traction engines started on 15 May 1923, and the line was officially opened on 10 July. and started using El 3 and El 4 locomotives. The full ore trains operated at 60 kilometres per hour (37 mph), while the empty return trains operated at 70 kilometres per hour (43 mph). NSB operated the trains using their rolling stock from Narvik to Abisko, where there was a change of locomotive and operating company.

Altogether these transmission lines, with their gaunt steel pylons straddling the bleak fells and deserted forests, cover upwards of 316 route miles. The sub-stations are situated at intervals of twenty miles from one another. By June 14, 1923, electric traction was in operation throughout between the Gulf of Bothnia and the North Atlantic coast at Narvik. Since that date the whole of the traction on the Ore Railway, and all the machinery used in connexion with the workings at Gallivare and Kiruna, have been operated by energy drawn from the fall of the Lapland rivers. Nature, the old enemy, was thus tamed by the engineers into becoming the prime mover. To regulate the flow out of the Suorva Lakes, feeding the works at Porjus and Harspranget, experts sent into the North by the Government decided to throw a dam or barrage across the Great Lulea River at a point near where it leaves the Lakes at the beginning of its downward course. Their preliminary work began in 1919, and they undertook it at a point near the head of the river where it was divided into two channels. Across the western channel they built a dam with no outlet. For the eastern channel they provided two tunnels passing under a dam equal in height to the western dam, the water being headed up 343 feet. The tunnels are not incorporated in the dam itself, for the builders bored them through the solid rock underneath. One of the tunnels is sufficient to regulate the flow, the other being provided as a stand-by.

Protection of Machinery from Ice

Passenger Trains also ran on the Narvik Line

The ice formations in the Lapland rivers presented a formidable problem to the builders of dams and hydro electric installations. They had particular trouble in rapids situated above power plants. “Anchor ice” formed on the boulders at the bottom of the stream. In due course this ice became loosened, was carried down and formed dangerous jams. Moreover, the agitation of the water in the rapids caused it to be additionally exposed to the cold air above and to form ice needles. These ice needles, as they accumulated, resolved themselves into troublesome ice sludge, which was aggravated by the presence of snow blown into the current from the banks. At the generating stations, too, those responsible found themselves facing serious difficulties from ice. The turbines, being built on an enormous scale, suffer little from ice sludge, but the screens covering the turbine intakes became clogged with it. The engineers adopted two methods. One consisted of heating the screens by electricity, thus thawing out the sludge as fast as it adhered. In other instances they removed the screens altogether. At the sluices the ice at first tended to choke the rolling sluice gates and to pack up in the intakes. The experts overcame these troubles by electrically heating the gates, as they had the turbine screens, and by providing a kind of wooden flooring for the intakes, under which they drew hot air from the generating house.

The Suorva Dams are situated some distance above Porjus. This is the nearest point on the railway, and there was no road, the only means of surface communication being by boats on the navigable parts of the Great Lulea and by sledge in winter. Yet there the Swedish engineers set up their two great dams, building them of the native stone. Aircraft solved one problem of communication, the aeroplanes being mounted on floats in summer, when they alight on the calmer water of the Great Lulea, In winter ordinary land aeroplanes are in use, these having skis substituted for the usual undercarriage. At Narvik, the Ore Company has its great quays and loading appliances on the shores of the Ofot Fjord, a vast, weird sea loch running in among precipitous mountains. Alongside the quays may be seen steamers waiting to carry the ore away to all parts of the world. A representative example of an iron ore steamer is the Sir Ernest Cassel, of 7,739 tons gross. In appearance she resembles a huge collier, with the engine-room and cabins right aft, a small navigating bridge amidships, and most of her space given over to holds.

Swedish Iron Ore, Germany and the Finnish perspective

Finland had long factored access to the external world via Sweden and the Narvik link in to military strategy in the event of a war with the USSR. What had not been factored in was the impact on this strategic assessment of a European War involving Germany at one and the same time. The Munich Crisis of late 1938 had led to a rapid and complete reanalysis of the situation – and the prognosis gave cause to serious concern.

Narvik in 1924

In 1915 (during WW1) British warships had violated Norwegian territorial waters to seize a German steamer inside the three mile limit. And near the end of the First World War the British, Americans and French had induced the Norwegians to allow the Skjaergaard to be mined in order to prevent German ships and submarines from using their territorial waters as a way around the Great Northern Barrage, a massive minefield laid from Scotland to Norway as part of the earlier allied blockade strategy. Suomen Maavoimat intelligence indicated that Germany in 1937 had received 20m tons of iron ore overall from various foreign sources. Although she was able to produce around 10m tons of her own iron ore each year, it was of low grade quality and needed to be mixed with high grade material from other countries such as Sweden, which annually supplied her with 9m tons (7m from Kiruna and Gallivare in Lapland and 2m from the central Swedish ore fields north-west of Stockholm. There were two main routes by which iron ore was shipped to Germany from Sweden.

The Eastern Route: From May- November, ore from the Northern region was shipped from the port of Lulea down the Gulf of Bothnia to the German north Baltic ports at Lubeck, Swinemunde and Stettin. Outside these months, the Gulf of Bothnia froze over, severely restricting supplies, and although an alternate port was available at Oxelösund, south of Stockholm for the transport of iron ore from the mines in Bergslagen, this facility was unable supply the full amount required by Germany, and in any case froze over herself from March – January each year. And while in 1938, Finnish icebreakers kept the sea-route to Lulea open for much of the winter season, it was estimated that even when Lulea and the Baltic ports of Oxelosund & Gavel were open it could only supply around 8m tons or less than half pre-war imports. And by 1938 much of this was carried in Finnish ore carriers – a trade which would itself be under serious threat in the event of a war with the USSR. The Finnish assessment concluded that in the event of the USSR attacking Finland while a state of war existed in the rest of Europe (and more particularly, between Britain/France and Germany), Germany would have no choice other than to transport the majority of its ore along the sea route down Norway’s heavily indented Western coast from Narvik. This in turn would in all likeliehood provoke a British attack on the German ships and possibly Narvik – and this was the port and rail route that Finland was counting on for access to what would be vital military supplies in the event of a war with the USSR. “Serious concern” was an understatement as this realization dawned on the Finns.

Steamship SIR ERNEST CASSEL (photo in Narvik)

The Western Route (The ‘Norwegian Corridor’, Western Leads or Skjaergaard): The port of Narvik, high above the Arctic Circle was open for iron ore shipments all year round. The photo here is of the Steamship SIR ERNEST CASSEL in Narvik, a Swedish steam-engined ore carrier of 7,773grt built in 1910 by Hawthorn Leslie, Hebburn, England. In 1921 she was sold and renamed ERNEST SS for Bolten, Millers NFL. In 1922 she was again sold and renamed SIR ERNEST CASSEL SS when purchased by P. A. Welin. Sweden. On the 16th April 1941 she was sunk by gunfire from the German raider Thor.

But the stormy Atlantic coast of Norway in WW1 had provided another extremely useful geological feature for Germany in her attempts to continue shipping the ore and beating the allied blockade. Immediately offshore from Norway’s western coast lies the Skjaergaard (Skjærgård), a continuous chain of some 50,000 glacially formed skerries (small uninhabited islands) sea stacks and rocks running parallel to the shore. A partially hidden sea lane (which Churchill called the Norwegian Corridor) exists in the area between this rocky fringe and the coastal landmass proper. Inside this protected channel it is possible to navigate the entire 1,600 km length of the Norwegian coast from North Cape to Stavanger. Such coastlines, sometimes known as Leads – a rough English translation for the common Norwegian nautical term Ledene (shipping lane) are common around Scandinavia – Skjaergaard also exist along the Swedish and Finnish Baltic coasts and off Greenland.

In WW1 the Germans had made great use of the Norwegian Corridor to avoid the attention of the always watching Royal Navy and the Finnish Military Intelligence assessment was they would do so again. Up until the time of the Munich Crisis, Finland had not invested any significant effort in a military analysis of the ramifications of another European War. Finnish resources had been largely concentrated on the ever-present threat from the USSR and with Finland having good to close relationships with ALL the major European Powers, no real attention had been paid to the geo-political ramifications of such a conflict. Following the Munich Crisis, the blinkers had been lifted and in the rapid reassessment that followed, the blunt Finnish Military Intelligence assessment was that a steady stream of German iron ore vessels ould attempt to make the long trip south from Narvik, sometimes within the three mile curtilege of neutral Norwegian territorial waters, sometimes just outside if the way appeared hazardous or the sea particularly turbulent. At the southernmost point the iron ore captains had to make a choice:

1) Follow the Skjaergaard around the coasts of Norway and Sweden, down through the Kattgat and finally into the north German North Baltic ports of Lubeck and Stettin. This route was safer because it brought them much closer to the protection of the German naval patrols and Luftwaffe air cover but involved hauling the very bulky and heavy iron ore the long way overland to the industrial centres on the heavily overburdened German railway system

2) Leave the safety of the Skjaergaard and make a dash south across the Skagerrak, (the sea channel north of the Danish Jutland peninsula) and hurry down the west coast of Denmark to Hamburg and Bremen. This was the preferred route because it allowed the ore to be taken straight along the efficient inland waterways to the industrial heartlands of the Ruhr and the Rhineland where it could be processed. It was however much more hazardous, putting the ships and their precious cargo at the mercy of what were anticipated to be the waiting allied submarines and patrolling destroyers – as had been the case in WW1.

In the event of a war involving Germany vs Britain and France, the Finnish assessment was that Swedish iron ore (and Finnish iron ore from Tornio together with Finnish Nickel and Copper for that matter) would be an important economic factor for Germany and shipments to Germany would as a matter of course be a target for the Royal Navy. The importance of these shipments would be increased after other sources were cut off from Germany by a British sea blockade as was the case in WW1. On the beginning of hostilites, Britain and France were to be expected to re-enact a repeat of the blockade system used to great effect throughout the previous war. They would be able to do this because they had vastly more powerful naval forces at their disposal than Germany, a country lacking in natural resources and heavily reliant on large scale imports of a wide range of goods. And the material Germany needed above all others was iron ore, a steady supply of which was imperative in the creation of steel which would be needed to sustain her war effort and general economy.

With any declaration of war and the start of the blockade, much of the foreign supplies of iron ore would be lost to Germany. Germany could be expected to retain access to 3 million tons per annum from neutral Norway and Luxembourg, but the 10 million tons from Lorraine in France and the supplies from Morocco and Spain were lost to her, and so the remaining supplies from neutral Scandinavia would become of crucial importance. Grand Admiral Raeder, head of the German navy, had been recorded as declaring that it would be “utterly impossible to make war should the navy not be able to secure the supplies of iron-ore from Sweden.” All of this meant that access of Finnish shipping to Narvik was now a high-risk proposition.

Regardless, following the Munich Crisis, other measures were taken to improve the ability for Finland to use the Narvik Line for importing of military supplies in a war-emergency situation. Forseeing the possibility of Finland having to rely on Narvik for imports, the government directed Valtionrautatiet / Statsjärnvägarna (State Railways) to begin constructing a large number of oil-tanker wagons to facilitate the importation of Oil via the Narvik rail link. This was not complex engineering, and progress was steady over 1939, so that by the time of the Winter War, a considerable amount of rolling stock suitable for the transport of Oil had been built up. As an insurance program in the event of war, it was a surprisingly successful move – of course, once Norway was invaded by the Germans, ensuring shipments of Oil arrived at Narvik then became the problem. But at least in the early months of the Winter War, once it was at Narvik, transport to the Finnish Oil Refinery was not an issue.

These oil-tanker wagons were also designed and built with axles and wheels that could be adjusted from the Swedish to Finnish gauge and special equipment was installed at the Tornio railroad station to allow for adjusting the gauge of these specially fitted train wagons so there is no longer need to cross-load the cargo. An effort was also made to construct a number of standard freight wagons along the same lines and these were built and used by Valtionrautatiet on the Finnish rail network – but were available to be relocated if necessary in the event of war. After negotiations between the Swedish and Finnish governments in early 1939, Valtionrautatiet had also ordered six El 4 locomotives for use on the Narvik Line – only two of these had been delivered prior to the outbreak of the Winter War and the consequent shortage of electric locomotives proved to be a bottleneck, limiting the number of trains that could be run down the line.

Further Contingency Plans

As a result of increasing tension within Europe, the above analysis and the dawning realization of the serious danger to Finland, two further contingency plans for emergency ports were drawn up. The first and perhaps the most obvious was to use the Finnish port of Petsamo in Northern Finland. The other, based on the recent use of Lyngenfjord in Norway as an access route in WW1, was for the use of Lyngenfjord in Norway. The Map below is post-WW2 but it shows the Finnish road link to Norway that runs parallel to the Swedish border – this is the route of the Lyngenfjord Highway – Lyngenfjord is where the highway from Finland now links to the main North-South highway through Northern Norway (at the time, in 1938, there was no North-South Highway, merely a road constructed for reindeer and sleds that was only navigable during the winter months).

(OTL Map from Post-WW2) …but it shows the Finnish road link to Norway that runs parallel to the Swedish border

Lyngenfjord, showing the terminus at Skibotn

It was decided that work to implement Lyngenfjord as a contingency port would begin immediately with the construction of a dual lane all-weather highway taking priority. Work on a Rail link to Lyngenfjord would begin simultaneously but was expected to take longer to complete than the Highway. A 116 mile long line already ran in the right direction – the Kolarin Rata (Kolari Railway) from Tornio and Kolari. The railway was not electrified and it was the standard Finnish broad gauge, inter-connecting to the Oulu–Tornio railway in Tornio. The first 49 miles from Tornio to Kaulinranta had been built in 1928, and with the opening of the large-scale Rautuvaara iron ore mine in 1935 to feed the steel mills of Tornio, the railway had been extended over 1933-35 the remaining 76 miles to Kolari, with a 12 mile extension to the mine of Rautuvaara (in 1937, the Äkäsjokisuu had been brought into production). These mines were the primary reason to extend the railway north of Kaulinranta and the fact that this had already been done served Finland well.

Thus, a sizable chunk (116 miles) of the 350 mile route from Tornio to Lyngenfjord had already been finished, with both a road and a railway line in existence. As it stood, the reasoning behind the construction of the Lyngenfjord Highway was straightforward. In the event of a war with the Soviet Union, it was entirely likely that Finland’s main trade routes by sea through the Baltic to the rest of the world would be cut off. And while Petsamo provided an all-year round ice-free port, it was both undeveloped and entirely too close to the border with the USSR. Strategically, building a good all-weather route to Petsamo and upgrading the port facilities would not alleviate Finland’s strategic exposure but would rather make her more vulnerable in the event of a Soviet attack.

While building a highway to Petsamo was seen as a strategic risk given the proximity of the port to the border with the USSR, the cost of building two major highways simultaneously was also considered prohibitively expensive – so the decision was to concentrate on the Lyngenfjord option as being the most strategically sound alternative. This was undertaken as an emergency program, with Maavoimat engineering units and private construction firms organized in late 1938, negotiations with the Norwegians to secure Norway’s agreement, equipment and supplies stockpiled over winter and work beginning early in the Spring of 1939. Confident in their own neutrality, and more than happy at jobs for Norwegians being financed by someone else, the Norwegian government made no objections and indeed, actively facilitated both the Highway Construction Project, the simultaneous Rail Link Project and the construction of wharf facilities at the small Norwegian village of Skibotn, located on the southeastern shore of the Lyngen Fjord.

Lygnenfjord is a sheltered fjord in the Troms County of norther Norway, bordering the Finnmark to the northeast and Nordland to the southwest. To the south is Norrbotten Län in Sweden and further southeast is a shorter border with the Lapland Province of Finland. The Lyngenfjord Highway as it was eventually built terminated at the Norwegian village of Skibotn, located on the southeastern shore of the Lyngen Fjord. The distance by road to Kilpisjärvi, the northernmost community in the western “arm” of Finland, is approximately 50 kilometres (31 mi). Prior to the construction of the Highway and port facilities, the population of Skibotn was around 700 people. Skibotn was a large and well-protected anchorage and with the development of suitable wharfing facilities to handle larger amounts of cargo, proved to be of critical importance in the Winter War. By April ‘1940, Finland was using Lyngenfjord as a major transhipment point and a naval base for Finnish warships escorting convoys to the UK and across the Atlantic. As such, it was of critical importance to Finland and the securing of Lyngenfjord was the major reason for Finnish intervention in northern Norway during the German invasion.

The Construction of the LyngenFjord Highway

A road of sorts to Lyngenfjord already existed and had been used even prior to WW1, but for most of the route it was more of a mud track than a formed road – as most roads were in the back-country areas of Finland before the coming of the automobile. Still, it formed the basis for part of the route and it also allowed construction to start at a number of points simultaneously.

The construction of the Lyngenfjord Highway and the parallel Lyngenfjord Railway is a little known engineering epic which was not widely publicized at the time for security reasons. Perhaps the only comparable engineering projects of the WW2 period were the constructions of the Alaska Highway and the Burma Road – both of which came well afterwards. The construction of the Lyngenfjord Highway as an emergency measure had been sparked off by the Munich Crisis of September 1938 and the reasoning behind the decision to build this Highway and the parallel Railway have been covered in the previous post. The construction project itself was fast-paced from the moment the Go decision was made (in mid-December 1938). The epic project’s success was an illustration of all that had been achieved in Finland over the past 20 years – the ability of the politicians to come together and, on military advice, make a strategically necessary decision without the internecine bickering of party politics intervening. The ability of the military to mobilize and move rapidly in close partnership with Finnish companes – and it was the logging, construction and engineering industries that supplied the key expertise and construction resources.

The old road to Lyngenfjord in Winter

And it should always be kept in mind that while this was the largest and fastest engineering project undertaken in Finland to that date, major work was also underway that same spring and summer on the Karelian Isthmus, with many thousands of volunteers at work strengthening the defensive positions throughout the Isthmus. Over the spring and summer of 1939, Finland was humming with activity – the defence related manufacturing plants were working 24/7, military exercises were continuous, the Karelian Isthmus was like a next of disturbed ants and deep in the wilds of Lapland, 10,000 men from Suomen Maavoimat Pioneeri (Engineer) units working alongside a further 12,000 civilian contractors to drive the Lyngenfjord Highway through.

The route of the Tornio to Lyngenfjord Highway ran for 350 miles, traversing forests, crossing swamps, bridging numerous rivers and streams and finally piercing the Norwegian mountains before finally reaching Lyngenfjord. Fortunately, the first 100 miles to Kolari already existed, together with a railway, and this reduced the length of road and rail that had to be driven through to “only” some 250 miles. The decision to build had been made in mid-December 1938, but the fierce Arctic winter meant construction work could not start until March 1939 at the earliest. Those months were not idle ones – the first step in building the Highway was to determine its route – and route surveys were carried out through the dead of winter, largely following the old route to Lyngenfjord and assessing its suitability, gradients and creating maps to work from when work started. Leading the team of surveyors that winter was Tuomas Vohlonen.

Tuomas Vohlonen, leader of the Lyngenfjord Survey Team, Winter 1938

Tuomas Vohlonen (1878–1939 was a famous Finnish inventor and a surveyor by trade. In this photo, he can be seen taking a bearing with the compass he had designed and manufactured. Vohlonen was an experienced surveyor and a well-known member of the Suojeluskuntas. Vohlonen volunteered to lead the survey party on their two month long task. He died in the summer of 1939, shortly after returning from a trip to the Finnmark where he had completed a last detailed survey. His patents cover a wide area of devices and activities including compasses, skis, surveying, engines and farming. His most important heritage is the company Suunto Oy which is still active producing compasses according to his patented method as well as dive computers, outdoor wrist-top computers, and heartrate watches. In April 1933, after experimentation with various designs, Vohlonen applied for a patent from the Finnish National Board of Patents and Registration for a compact liquid-filled field compass, in which the magnetic needle and damping fluid were completely sealed into a unitary fused celluloid capsule. Volhonen was granted a patent on January 25th, 1935. Together with his wife Elli and nephew Kauko he founded Suunto Oy in 1936. Vohlonen incorporated his new liquid-filled capsule into a lightweight wrist-mounted design, the M-311, suitable for use by soldiers, surveyors, hikers, and others navigating whilst afoot. His march compass was adopted by the Suomen Maavoimat and was in widespread use throughout the Maavoimat by late 1938.

The leadership of the Winter Survey Team was to be Vohlonen’s last major accomplishment and one of which he was, justly, proud – in the summer of 1939 at the age of 61, shortly after his return from Kolari, Tuomas Vohlonen, surveyor, inventor and managing director of an emerging company whose efforts were now bearing fruit, died suddenly and unexpectedly. The most groundbreaking of Tuomas Vohlonen’s inventions was the method for manufacturing a liquid-damped march compass and it had been a proud moment for him when a militarised version had been adopted by the Suomen Maavoimat as the standard compass for its soldiers. (His company incidentally still exists and it continues to manufacture high quality watches and compasses – http://www.suuntowatches.com).

Construction equipment being assembled in Oulu prior to movement by Rail to Tornio where work would start in April’

Meanwhile, contracts with construction and forestry companies were being signed, materials stockpiled and plans were drawn up to mobilize a large number of Suojeluskuntas Pioneeri units and to hire construction labourers, loggers and all the ancillary personnel necessary for such a large scale project. It’s difficult now to imagine road-building conditions any worse than those workers faced in 1939, when they began carving the route through Lapland, over the mountains along the Norwegian border and through to the remote Lyngenfjord village of Skibotn. ‘Men hired for this project will be required to work and live under the most extreme conditions imaginable,’ read one advertisement for volunteers. ‘Temperatures will range from 90 degrees above zero to 70 degrees below zero. Men will have to fight swamps, rivers, ice and cold. Mosquitoes, flies and gnats will not only be annoying but will cause bodily harm. If you are not prepared to work under these and similar conditions, do not apply.’ Needless to say, thousands of men applied and, inline with the large numbers of volunteers who were at the same time working on the defences of the Karelian Isthmus, large numbers of students also volunteered, making up in enthusiasm what they lacked in skill.

Commercial Wharf construction underway: Summer of 1939′

Personnnel who had been recruited, together with as much equipment as possible, were moved up to the starting points along the route before winter had ended. They more often than not had to hastily construct their own accommodation on arrival – no great problem for Finnish loggers used to working in the forest over the long Finnish winters but a little more challenging for city boys whose experience of living in the forests was limited to their military service. Living arrangements weren’t that harsh (there were at least tents and a mess hall for the road builders), but working conditions left much to be desired. After arriving at their destinations, workers began clearing and stockpiling timber until the spring thaws made it possible to begin the real construction work.

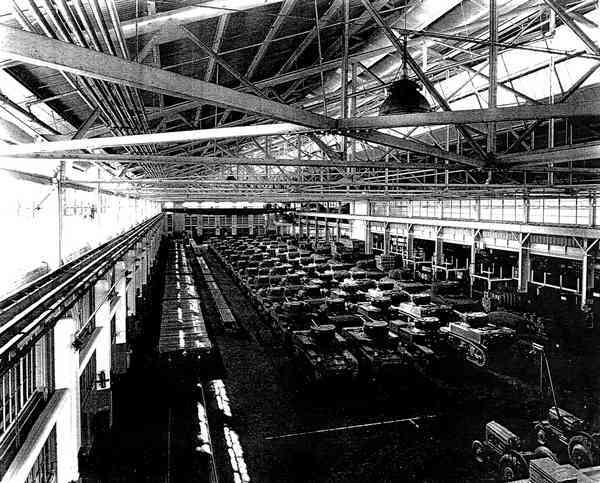

By early March 1939, construction equipment was already being assembled in Oulu prior to movement by Rail to Tornio where work would start in April. This was the largest engineering project of its kind undertaken in Finland and would not have been possible without the 3,500 different vehicles assembled, including 1,750 heavy trucks, 500 bulldozers and tractors, 500 diggers, graders and rollers and 750 other assorted vehicles including buses and trucks to transport the workers to and from work sites. Equipment was assembled, first around various sites in Finland and then moved to Tornio, Kolrani and by ship to Lyngenfjord itself – with work planned to start from all three points simultaneously. Within the project, there were a number of sub-projects that were to kick-off at more or less the same time, with some variability for the weather.

Warehouse facilities at Lyngenfjord later in WW2. American equipment is begining to arrive…

Commercial Wharf construction was underway by the summer of 1939. Wharf facilities were constructed rapidly, but the scale and size of the planned port facility meant that work was still underway as the Winter War broke out. In the event of a war, it was envisaged that military supplies would be arriving in crates or boxes, which would necessitate the use of shore cranes to speed upoffloading. In the event, shore cranes were not available at the start of the Winter War and cargo ships had to use their own cranes – although the situation was partially alleviated by the relocation of one of Finland’s two heavy-lift cargo ships to Lyngenfjord. It was expected that wharf, warehouse and barracks construction in Lyngenfjord could start first, and the men and materials for this component of the project were dispatched by ship in late January 1939 – as soon as the necessary materials had been purchased and loaded and the workers assembled. Planning for the port was based on the projected needs of the Finnish military in the event of a war with the USSR and was based on estimates of “discharge capability.” The ability to export via the port was considered a secondary benefit in the initial stages, and later in the WW2 period, much additional work was undertaken to allow large volumes of exports to be shipped out, as well as military supplies shipped in.

Surveyors setting out the route for the Highway. Generally, this followed the existing route

The first priority was simply to survey the route and blaze an initial track over which trucks could move

Wharf facilities were constructed rapidly, but the scale and size of the planned port facility meant that work was still underway as the Winter War broke out. In the event of a war, it was envisaged that military supplies would be arriving in crates or boxes, which would necessitate the use of shore cranes to speed upoffloading. In the event, shore cranes were not available at the start of the Winter War and cargo ships had to use their own cranes – although the situation was partially alleviated by the relocation of one of Finland’s two heavy-lift cargo ships to Lyngenfjord.

The port facility was designed for military usage initially, but commercial considerations were also kept in mind, and the facility was designed to handle 2,000 tons of cargo per day – handling four ships simultaneously at an estimated 500 tons per ship per day offloading capacity using ships derricks and wharf-based cranes. This would then need to be moved from the docks to warehousing facilities for loading onto available transport (rail or truck). A major advantage here was that with Finland being an export-based economy, and with most exports leaving via ship, a large amount of expertise in this area was available. Consequently, the needs were well-understood and planning was effective. A further major consideration at Lyngenfjord was the construction of storage and warehousing facilities as well as marshaling yard capacity for both trucks and, eventually, for the planned rail link. Three marshaling yards were built – the first for trucks with a capacity for an estimated 1,000 trucks, the second and third for railway wagons, with a capacity for 700 wagons in the first yard and 800 at the second.

Work begins by clearing the route

Heavy construction machinery was used wherever possible

Work on the cleared route then began

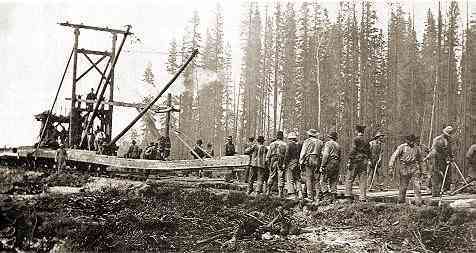

Building a Log Bridge

Building a more permanent bridge to replace an earlier log bridge

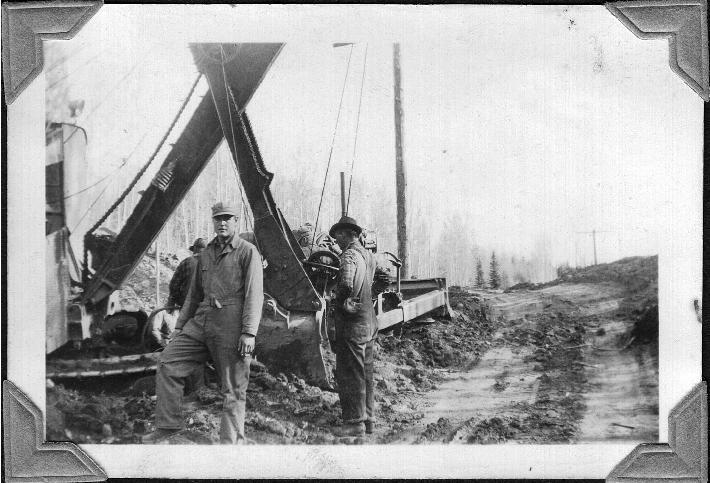

Crane Shovel putting in a Culvert

And last of all, over everything came a thick layer of gravel which was packed down by rollers

Building the highway up the side of a small lake as the Norwegian border was neared

The pace was rapid, risks were taken and accidents happened all the time.

And a truck that had rolled over…

Construction on the Lyngenfjord rail line went on in parallel, albeit slower

The construction of the Lyngenfjord Highway started a little later, in March 1939. Large amounts of material and equipment had already been moved and stockpiled over the winter months and startup was immediate, taking place as soon as weather conditions permitted. Teams of surveyors spread out over the length of the planned Highway, laying out the road in detail. The first priority was simply to survey the route and blaze an initial track over which trucks could move in men and materials to improve the route while also moving men and materials into place for work to start.

As the weather conditions improved, equipment and men began working from Lyngenfjord, Kolrani and Tornio simultaneously. The Tornio-Kolrani section was perhaps the easiest – the work here was simply to upgrade the existing road to a dual-lane all-weather highway on the one hand and to lay a second railway line on the other, effectively double-tracking the line as far as Kolrani. This work was not trail-blazing, and standard rail and road construction techniques were used. Work progressed rapidly on this part of the project with multiple start points being used and large teams at work, covering the distance rapidly.

The Winter Survey had laid out the route in broad detail, mapped the path through the mountains and generally confirmed the viability of the existing road as a baseline from which to work. For the detailed work on the Lyngenfjord Highway project, much of the surveying during the project itself was accomplished by “Sight” Surveying – using the original survey as a guide to the general route and direction whilst accomplishing the immediate objective by climbing a tree or standing on a bulldozer, picking the next point in the distance and working toward it while at the same time attempting to avoid the numerous small swamps, rivers and small lakes, rock outcroppings and steep grades. Local guides were employed where needed to help the surveyors.

The first priority was simply to survey the route and blaze an initial track over which trucks could move in men and materials to improve the route while also moving men and materials into place for work to start. The warmer weather only brought new hardships. Rivers flooded. Truck wheels were trapped in dense, grasping mud. Equipment became caught in forest fires. And Lapland mosquitoes proved far more troublesome to the men than any theyd experienced before. ‘You had to eat with your head net on,’ one construction worker recalled, ‘you would raise the head net, and by the time you got food on the spoon up to your mouth it would be covered with mosquitoes.’ The land on which the new highway was being constructed stubbornly resisted taming. Most of it was covered for as far as the eye could see by dense forest or boggy patches of swampy ground. The earth was so swampy in places that road builders could make progress only by laboriously felling trees and laying them down, side by side, layer over layer, to form a ‘corduroy road,’ a surface that would shift and buckle as the ground dried. Corduroying required first a layer of logs, then the dumping truckloads of earth and gravel on top of that to provide a usable road surface.

These of course were expected problems and the men knew how to deal with them. But the effect of the cold weather on the heavy equipment before the thaw was another problem. As another worked noted, ‘Swift moving Lapland streams resisted freezing and the underside of trucks that crossed them became ice coated . . . . After driving through water it was absolutely necessary to keep the vehicle moving, as ice would lock the wheels of a truck that stood still for a few seconds (not minutes, seconds), and any attempt to move forward would snap an axle.’ He added, ‘Trucks with bent frames and beds and distorted springs moved crabwise up the road. Some trucks broke in half, were left beside the road as derelicts until they could be recovered later. Men suffered but held up rather better than the equipment on the whole.’ After the thaw, it was the terrible mud that slowed the vehicles – and the rapid construction of the corduroy road-base was essential to keep progress rapid.Layers of logs sank quickly into the seemingly bottomless mud and had to be added too continuously, interlayered with truckload after truckload of gravel until at last the entire mass stabilised.

Behind (and ahead of) the bulldozers clearing the route, the loggers felling the trees and the trucks dumping gravel, other teams built culverts or temporary bridges, dug ditches to keep the road surface relatively dry, put down additional base material and in soggy sections laid down a wooden bed consisting of a several feet thick layer of trees. This “corduroy road” would then be covered with gravel and packed down, ensuring that supplies and fuel continued to be moved forward to the teams at the front. Finally, the largest “finishing teams” would follow as close behind the bulldozers as possible, widening and straightening the road, eliminating some steep grades, and covering surfaces with even more gravel, then packing this down. The initial result was a passable military road 18 to 24 feet wide, far below the standards required for a safe civilian highway but adequate for military trucks. Construction teams further to the rear – usually some 10 to 20 miles back – worked to widen the road to dual lane, build rest and refueling stops, build accommodation for the maintenance crews and construct shelters for their vehicles and equipment. The workers hacked, slugged and pushed their way through dense forest, hard rock, muddy bogs and mosquito-ridden swamps, working exhausting 12 to 16-hour days in harsh and often dangerous conditions.

One of the greatest obstacles faced was the lack of gravel or suitable rock to surface the road bed. The earth over which the road passes was a liquid mud when wet and it was sometimes necessary to haul gravel 25 to 30 miles from the nearest river beds where suitable rock could be extracted. Where sections of the Highway ran into soggy or swampy ground, this was overcome through the building of corduroy (or log) roads which provided a solid foundation over which gravel was laid. The sections laid down in this way formed a wooden bed consisting of several feet of logs over which a deep layer of gravel was laid and compressed. The resultant road was generally solid and where the logs were laid in wet, acidic, anaerobic soils such as peat they decayed very slowly. In constructing these roads it was important to select logs about ten inches in diameter and place them in several layers. As in the superstructure of a bridge, stringers, double layers of crossed logs, and siderail lashings had to be used. The guard rails had to be wired because nails could not be used. The cross logs had to be topped with a layer of sand – not dirt – or, when no sand was available, with cinders or gravel. Grading and leveling was done with whatever equipment was to hand… and there was a great deal of improvisation – something the Finnish logging and constructions workers excelled in. Such thoroughly constructed corduroy roads could stand the strain of constant heavy traffic.

Speed was essential and timber was easily available – all the early bridges were built from logs, although many were later replaced with steel “Bailey Bridge” style construction. The log bridges could be constructed rapidly from immediately available materials – the bridge in this photo took a mere three days to build. Teams all along the surveyed route built bridges as fast as possible while other work teams constructed the roads between the bridges. Numerous steel bailey bridges had also been pre-fabricated and stockpiled prior to work on the highway beginning. They were moved into position as soon as the road had gotten to a point where they could be moved up and put into place.

The hardest section of the road to build was that that ran through the mountains along the Norwegian-Finnish border. It was rugged terrain and while the route existed and was usable, it needed to be upgraded considerably to take a major Highway and then a Rail line. This section involved a considerable percentage of the overall 22,000 man work force and was completed in roughly the same timeframe – by late summer 1939.

The pace was rapid, risks were taken and accidents happened all the time. Vehicles and machinery were recovered wherever possible but speed was of the essence and if recovery would slow progress, the obstacles were simply pushed to one side and abandoned until later. Wrecked and abandoned vehicles were a common sight on the sides of the road as it grew in length.

Post-Construction Operation of the Lyngenfjord Highway

The final result may not have been pretty, but together with the parallel Lyngenfjord Railway it would prove to be Finland’s lifeline for 6 long years

Once completed the Lyngenfjord Highway (and later also the “Arctic Road” to Petsamo) required a substantial number of people to maintain and run the route. The Lyngenfjord Highway by itself required some 3,000 staff to carry out traffic management during the Winter War. There were about 2,000 jobs related to loading and unloading, road maintenance employed about 4,000 people in total and other services around 1,000 – in other words, almost 10 000 people were needed in one way or another to run the Lyngenfjord Highway (and the “Arctic Road” to Petsamo, which was also managed by Oy Pohjolan Liikenne Ab, required similar numbers of personnel from late 1940 on). During the Winter War, almost 75% of these 10,000 were women – and a large number of the men were Swedish volunteers.

The building of the Highway was an epic undertaking, but its opening at the end of summer 1939 was not mentioned in the newspapers – largely for security reasons. Meanwhile, work on running the rail track through to Lyngenfjord continued at the same breakneck pace that had seen the Highway driven through. The Rail link itself took longer, only being completed towards the end of 1940. Maintenance was an ongoing task in summer, as was snow-ploughing in winter. It was down this highway in the depths of winter that many of the Volunteer units that fought in Finland would come….At the height of the Winter War, some 500 trucks per day traveled in each direction on the road, with 2,000 trucks in use at any one time. Kolrani turned into a major cross-loading depot as trucks off loaded and transferred their freight to the rail system.

December 1939: Wedge and wing plow clearing the road.

At the same time as work on the Lyngenfjord Highway started, the State founded a transport company called Oy Pohjolan Liikenne Ab which would handle all cargo movement to and from Lyngenfjord (rail traffic to Narvik was handled by Finnish State Railways). At the same time as construction on the road started, an order for some 1,000 trucks was placed with both Sisu Construction Vehicles and with the Ford Helsinki Plant. Some 750 of these were standard heavy-duty militarized cargo trucks, but 250 were for an innovative and rugged 8 wheeled all-wheel drive military truck that could handle pretty much any type of conditions encountered on the Highway.

Designed to cope with swampy ground in summer and snow in winter, this had been designed in 1936 and trialed over 1937. The Maavoimat had already placed an order for 500 of these trucks in late 1937 – An order for a further 250 was placed by Oy Pohjolan Liikenne Ab in January 1939 for use on the Lyngenfjord Highway. Manufacture and delivery of these additional trucks had been completed prior to the outbreak of the Winter War. In addition, Oy Pohjolan Liikenne Ab liaised with private transport companies and the Maavoimat for the use of privately owned vehicles in the event of war. With the road completed in September 1939 and the basics of a port at Lygenfjord in place, the outbreak of the Winter War resulted in a further 1,000 privately owned trucks being contracted to work the route.

The Sisu-designed and built 4-axle 8×8 all-wheel drive Military Truck.

Contract carriers used their trade organisations (among them the Lapland Road Hauliers’ Association) to negotiate terms and fees with their employer. Negotiations were often necessary in connection with e.g. arrangements for loading and unloading, compensation for goods lost in transit, tariffs, road maintenance, insurance, and traffic safety. At this point, we’ll leave the details of the actual operation of the Lyngenfjord Highway until we get to the Winter War itself. Suffice it to say that as a project, the Lyngenfjord Highway construction project brought together the experience and knowledge of a range of Finnish companies and industries, but the glue that held it all together was the experience in rapidly building logging roads under rugged conditions that had been developed within the Finnish Forestry Industry through the 1930’s….

Two freight trains leaving the Lyngenfjord Marshaling Yards en route to Tornio, early 1941

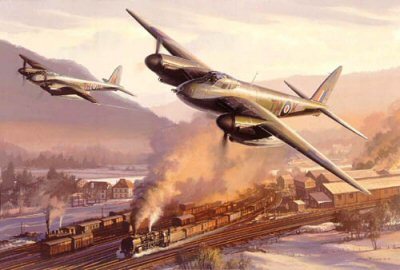

Ilmavoimat VL Wihuri’s heading down Lyngenfjord – late 1940

In the picture above, two freight trains are leaving the Lyngenfjord Marshaling Yards en route to Tornio, early 1941 – the rail link to Lyngenfjord was completed in September 1940 and freight trains began using the link within days. By 1943, a double track would be in place over the entire distance to Tornio, considerably speeding up transit times. Two Ilmavoimat VL Wihuri fighter-bombers based from the Ilmavoimat’s Bardufoss Airfield fly low overhead. In the second picture, Ilmavoimat VL Wihuri’s are heading down Lyngenfjord at the start of a lengthy coastal patrol flight in December 1940. Following the German invasion of Norway in Spring 1940, Finland would seize control of the Finnmark to protect access to Lyngenfjord and go on to build up her military strength in the area, including construction of a large air base at Bardufoss.

And a note: this is fictional, but a track of sorts to Lyngenfjord did exist prior to WW2 and in fact in WW1 was used to a limited extent to transport shipments from the UK through to Russia. From Tornio in Finland, the transport firm of Karl Boström ran a horse freight service via Kilpisjärvi to Lyngenfjord in Norway. This route was at its height in 1916, however in the year of the revolution in 1917 the trade to Russia dried up. While a good road now exists, no rail link has eventuated, although there have been proposals for one. The construction of the Lyngenfjord Highway and rail link in this alternative history is loosely based on the construction of the Alaska Highway in WW2 – a magnificent engineering project which proceeded at breakneck pace and in similar conditions to those that would have been experienced in constructing the Lyngenfjord Highway.

Copyright secured by Digiprove © 2013 Alternative Finland

Copyright secured by Digiprove © 2013 Alternative Finland